- 16. October 2024

- Intelligent Systems

High-current contacts for power electronics

Content you may also like

Niedernhall, 15 October 2024 – Würth Elektronik ICS will be exhibiting at electronica from 12 to 15 November 2024. Lead-free high-current contacts for PCB contacting will take centre stage at exhibition stand 334 in hall A2 at the Munich trade fair: LF PowerPlus 2.0 and LF PowerBasket. Also new: the PowerBusbars – customised and easy-to-install copper busbars. As the inventor of Powerelements for PCB contacting, Würth Elektronik ICS will be presenting the contacting of high-voltage components on PCBs for various applications.

With their contact springs, the lead-free LF PowerBaskets form a basket that is optimally designed to hold round contact pins. These high-current contacts therefore allow several mating cycles with low mating forces and, thanks to their positioning tolerance of 0.6 mm, are suitable for PCB connections with several connections. The PowerBaskets provide a pluggable connection that is reversible at any time, for example, for assemblies that need to be disconnected for maintenance purposes. The contacting of a 3-phase motor, such as that installed in an e-bike, is a classic application example. LF PowerBaskets are available in versions for press-fit technology, SMT and THT.

The lead-free LF PowerPlus 2.0 Powerelements consist of a brass base body and a stainless-steel screw element. As a result, they offer maximum torque at a comparatively low weight. The new screw tip makes it easy to insert and position the nut. This creates ideal conditions for automated screw connections. The special design of the base body allows the Powerelements to be fitted on both sides at the same position. Currents of up to 360 amps are possible depending on the version.

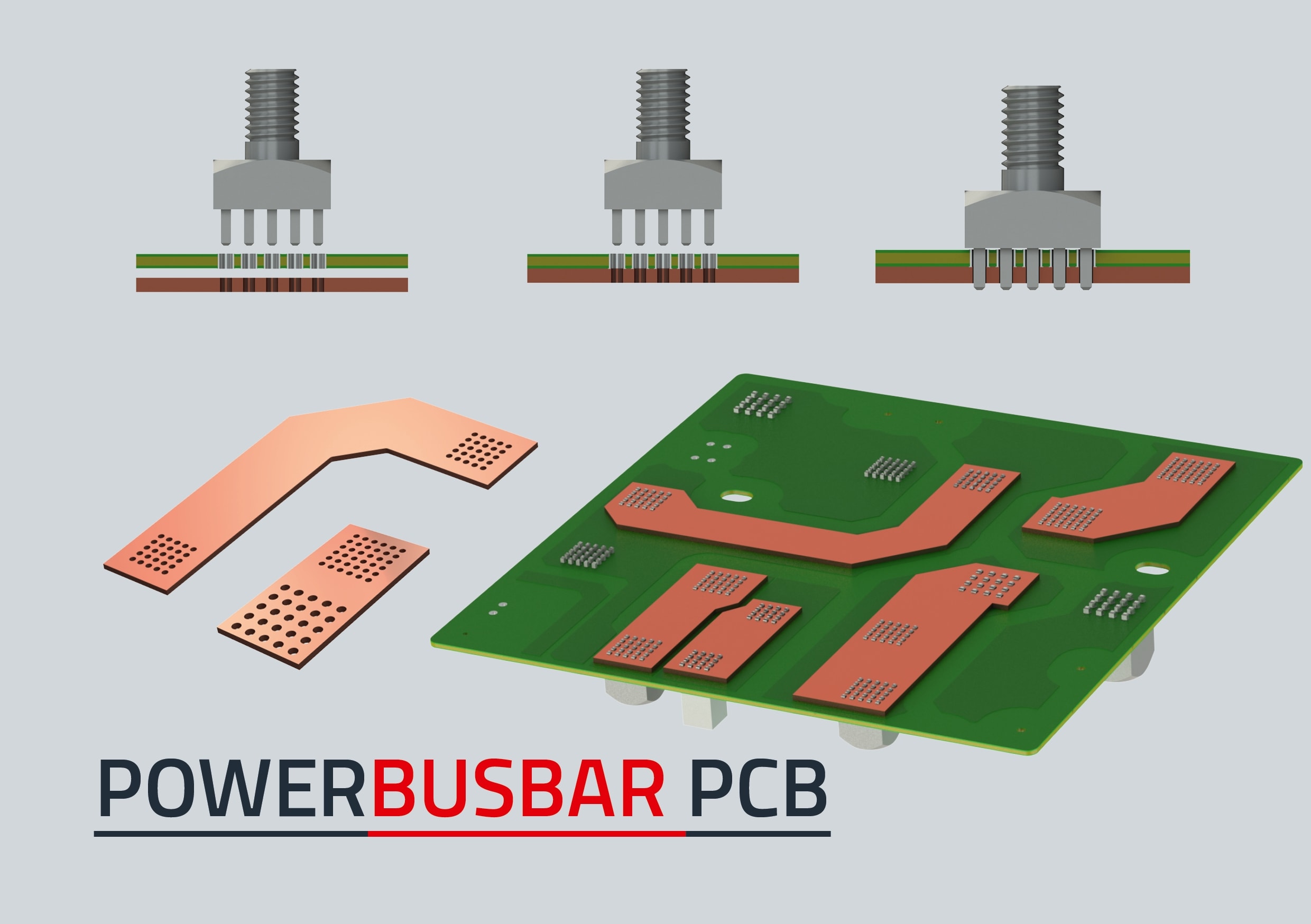

PowerBusbar PCB instead of additional copper inlays on the circuit boards

To increase the current carrying capacity on standard PCBs either selectively or over a large area, Würth Elektronik ICS offers PowerBusbar PCB, customised copper busbars that are pressed onto the PCBs. Thanks to the high thermal conductivity of copper, the PowerBusbar PCBs can efficiently dissipate heat from the overall system as well, helping to improve reliability and current carrying capacity while preventing hotspots. Installing the PowerBusbar PCB is quick and easy. The busbars are moulded together with the Powerelements from Würth Elektronik ICS and the PCBs in a single operation. Additional fastening of the conductor rails is not required.

Sample service for electronica

Würth Elektronik ICS will be offering a sample kit with a carefully selected collection of Powerelements at the trade fair so that visitors can explore the various applications of lead-free high-current contacts for themselves. It provides a perfect overview of the product range for developers. The sample kits will be handed out at the exhibition stand or can also be ordered online.