On this page you will find information and images for your journalistic reporting.

If you have any questions, please feel free to contact us personally at any time. Here you find our Press contacts.

In many miniaturized electronics applications, conventional cable wiring is both costly and material-intensive. It also limits the scope for innovation and product performance. The HyPerStripes (Hybrid integrated high performance electronic stripes) project addresses these limitations by developing

technologies and production processes for long, smart and flexible electronic systems that can replace conventional cables. HyPerStripes focuses on two key applications: On the one hand, on medical instruments used in minimally invasive procedures (e.g., catheters and implants); and on the other hand, on environmentally friendly LED lighting surfaces.

HyPerStripes project partners will create a technology platform including manufacturing techniques for roll-to-roll (R2R) processing as well as the integration of electronic components onto very long ("endless"), flexible and stretchable printed circuit boards. This will pave the way to higher-performance products and new applications, while reducing the cost and environmental impact of manufacturing. It will also strengthen Europe's global competitiveness in the production of flexible electronics and contribute significantly to sustainability in production and products. HyPerStripes is a European research project funded by Germany, Ireland, and the Netherlands.

In healthcare, miniaturization and flexible electronics have already brought valuable benefits. Minimally invasive procedures allow the investigation and treatment of diseases without major surgery. However, many of these devices, like smart catheters, still rely on “old-fashioned” wiring connection. Wiring is done by hand and can account for up to 80% of the product cost. It also affects reliability, manufacturing yield, weight, and resource consumption. A flexible, thin strip on which the hybrid electronic components (e.g., flexible and rigid) are integrated could solve these interconnection problems. This also opens up new applications in healthcare, particularly in patient monitoring, where the strips can address today's shortage of long, stretchable, and robust PCBs and interconnects. Similarly, long, flexible strips could enable new applications in LED lighting. For example, large, flat light surfaces could be developed that can be fully integrated into the glazing of buildings and ultimately mimic natural light. One of the main goals of HyPerStripes is to transfer this know-how to industrial production. This is done through an open, sustainable technology platform that offers printing technologies, lithographically patterned copper wiring systems, and low-temperature assembly steps – all in a single-source consulting and manufacturing platform.

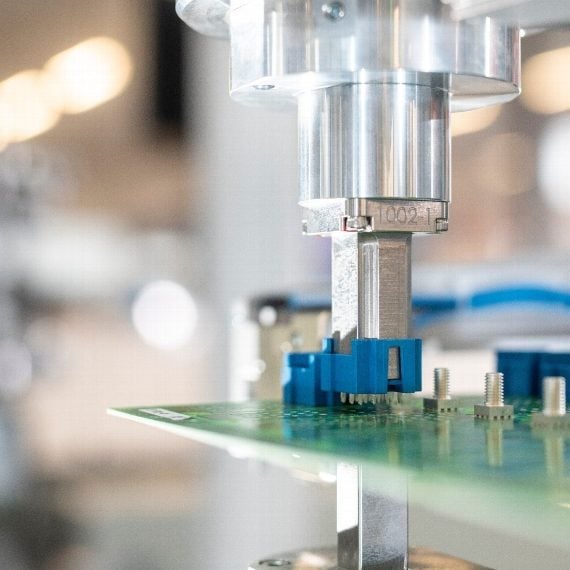

As the leading PCB manufacturer in Europe, Würth Elektronik will focus primarily on flexible and stretchable PCBs with roll-to-roll processing to enable virtually “endless” electronics with fine miniaturized structures. The aim of the project is to develop stretchable circuit carriers in lengths of more than one meter for cost-effective products and the corresponding manufacturing technologies.

About HyPerStripes

The three-year project started in April 2022 and has a project volume of €14.5 million (German Federal Ministry of Education and Research funding: €3.12 million). In HyPerStripes, 16 partners from three European countries are working together to achieve the objectives, including IMS CHIPS – Institute for Microelectronics Stuttgart, Fraunhofer EMFT, Nanowired GmbH, Capical GmbH, Philips Electronics Nederland BV, Philips Healthcare, Integer, and other participants from industry and trade. The network coordinator is OSYPKA AG.

About Würth Elektronik Circuit Board Technology

Founded in 1971, Würth Elektronik Circuit Board Technology is today Europe's leading PCB manufacturer, with national and international sales teams, 1,000 employees, 4,000 customers and an annual turnover in the triple digit million range.

Production takes place at three German plants (Niedernhall, Rot am See und Schopfheim) as well as with qualified partners in Asia. Whether basic or high-end technologies, customer-specific requirements are met from prototypes and samples to medium and large series. With the development of innovative product technologies, the company qualifies as a pioneer in the market.

Experts from the most diverse divisions provide intensive consultation and support, from the initial idea to the finished product and beyond. Würth Elektronik Circuit Board Technology sees itself as a reliable partner for both individual entrepreneurs and large corporations. The comprehensive portfolio is rounded off by an online shop, where PCBs can be ordered around the clock.

Würth Elektronik. More than you expect!

Do You Have Any Questions, Comments or Requests Regarding our Press Work?

Würth Elektronik EMV & Inductive Solutions

Sarah Hurst

Phone: +49 7942 945-5186

E-mail: sarah.hurst@we-online.com

Würth Elektronik Circuit Board Technology

Melanie Wöhrle

Phone: +49 7940 946-5932

E-mail: melanie.woehrle@we-online.com

Würth Elektronik Intelligent Power & Control Systems

Sandra Herter

Phone: +49 7940 9810-1503

E-mail: sandra.herter@we-online.com

Here You Can Download the Press Information and Pictures of the Company Area

Reference Guides, Technical Reports and Other Information Material

Würth Elektronik blog

Learn more about electrical design, new technologies and current innovations in our blog.