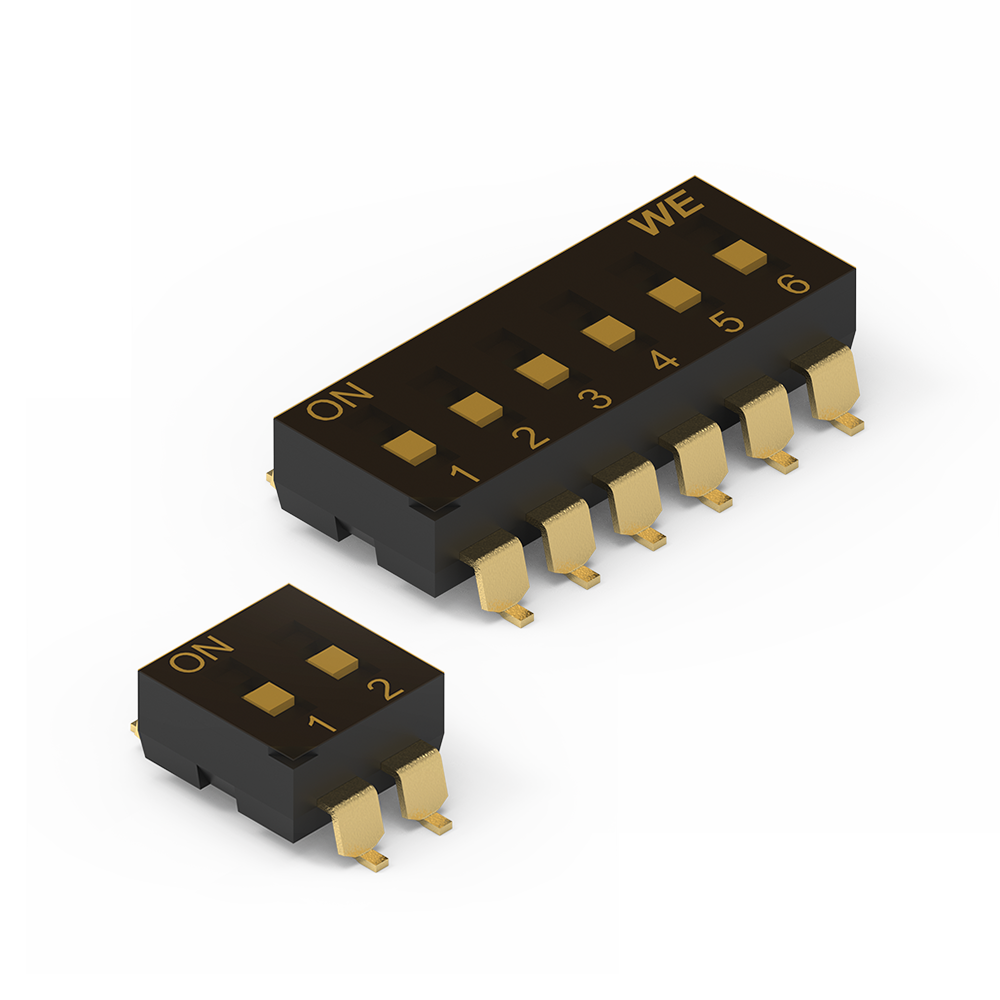

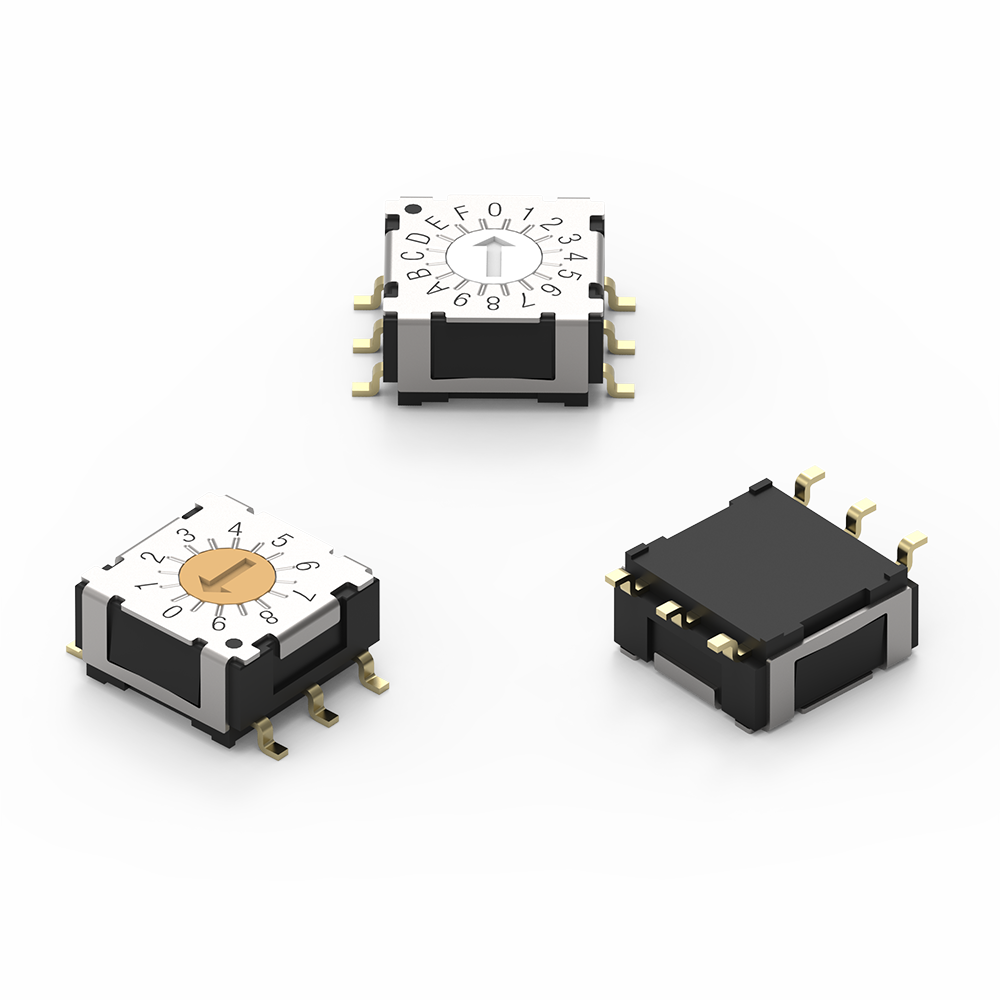

Convenience, safety and access to a whole range of functionalities - this is what electromechanical components make possible. Even when used in harsh environments, switches and pushbuttons for IP applications easily meet the requirements. In collaboration with IBL-Löttechnik, Würth Elektronik eiSos

has investigated the extent to which these are also suitable for the vapor phase soldering process.

Boiling Process

Solder Process

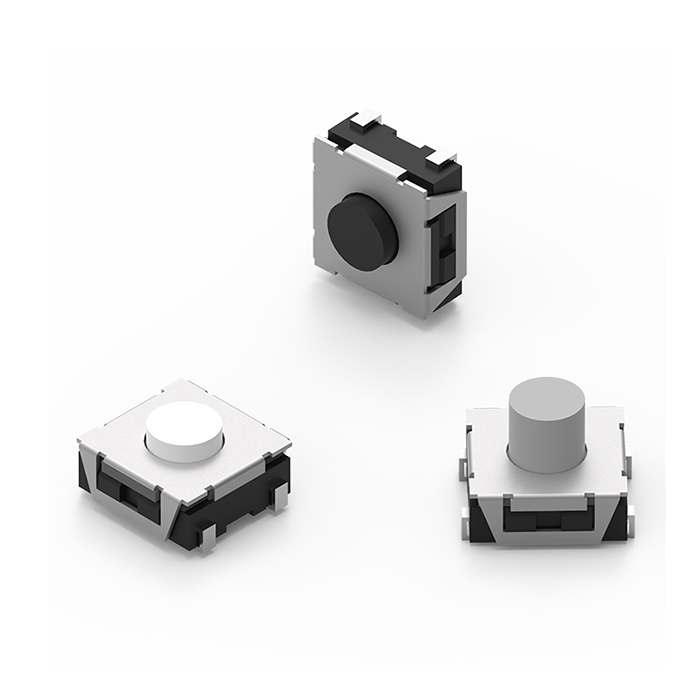

Tact Switch 6x6 mm IP67

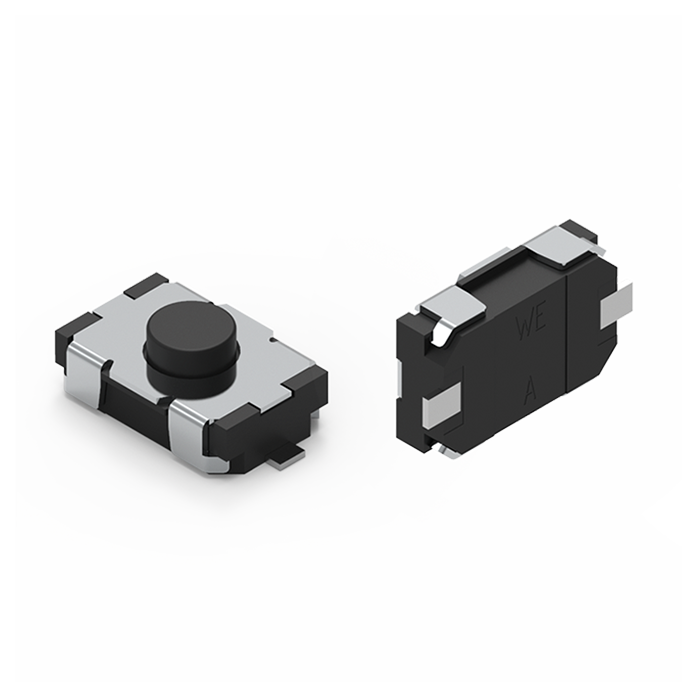

Tact Switch 6.2x4.1 mm IP67

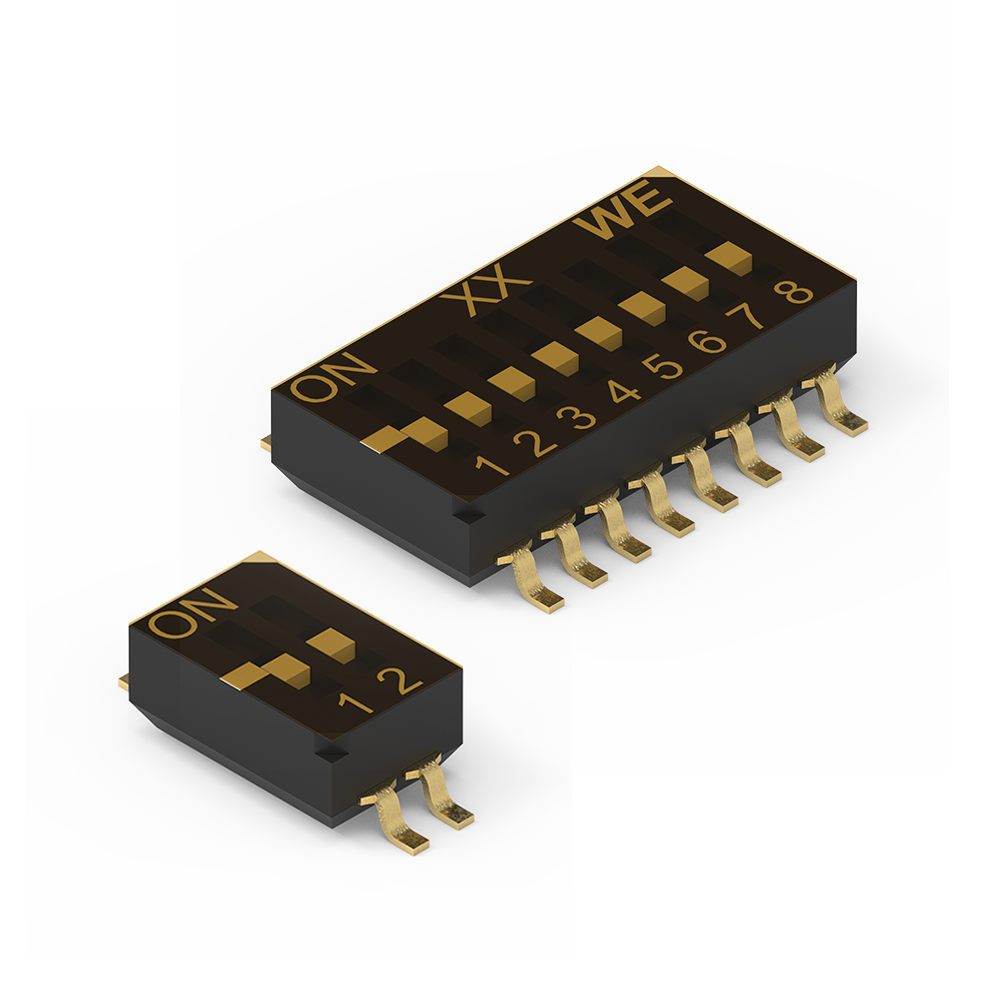

Rotary Switch 7x7 mm

The first step in the test series was to measure the initial contact resistances of the various switches. A leadfree, no-clean solder paste was first applied to 160 mm x 100 mm test boards and the electromechanical components were assembled manually by Würth Elektronik.

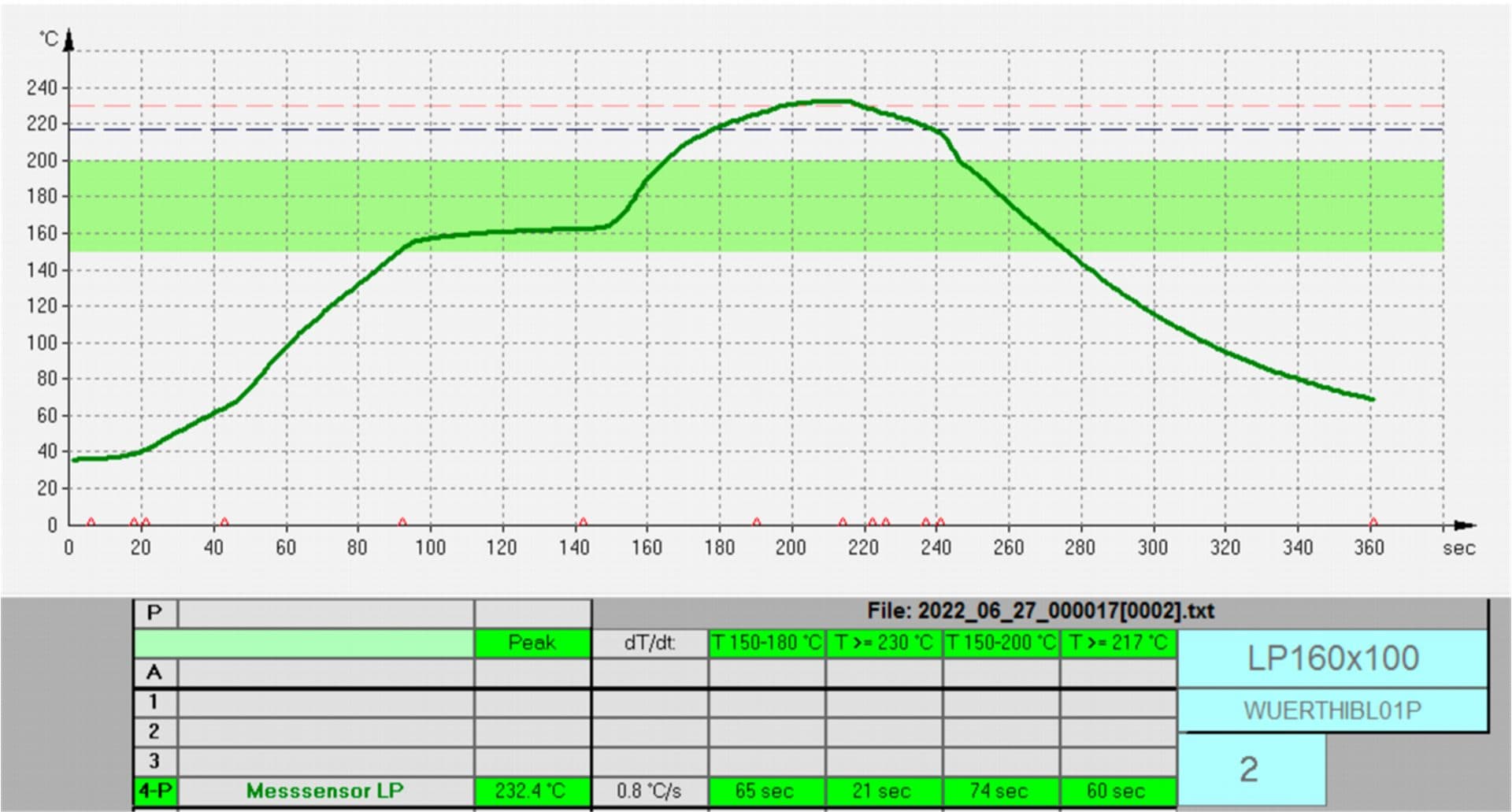

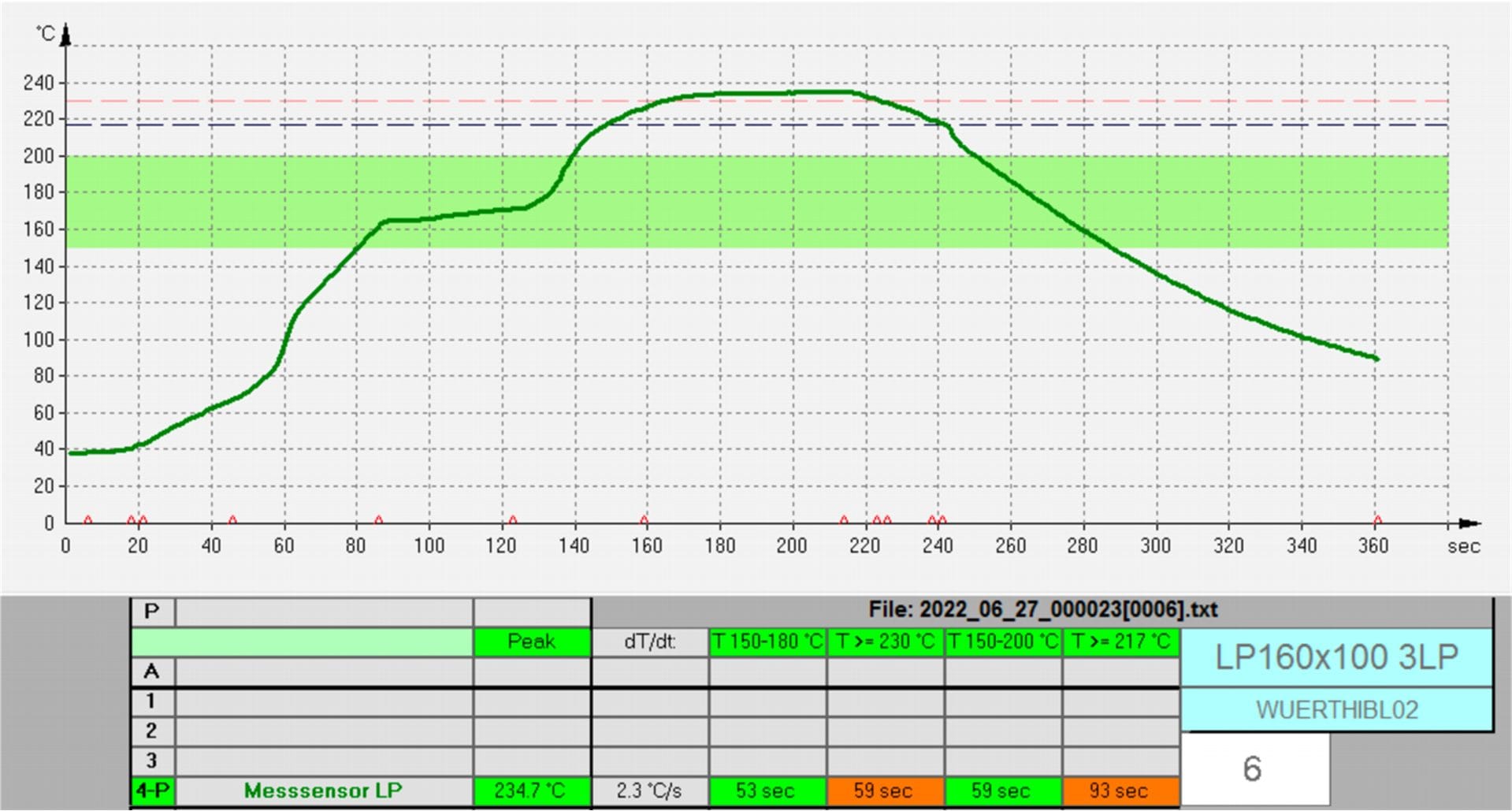

In several batches, the test boards underwent the vapor phase soldering process in the VAC 745 vapor phase soldering system from IBL Löttechnik.

In addition to typical standard soldering profiles, the electromechanical components were also subjected to a soldering profile that reached the load limit in terms of running time and maximum temperature. Some batches were run through the vapor phase process up to five times in order to meet the maximum requirements of five reflow cycles to which a component may be exposed according to the IPC (TM-650).

Finally, Würth Elektronik comprehensively tested the components in its test laboratory with regard to the reliability of the solder joints and the electrical properties of the components.

This temperature/time profile shows the standard soldering process: Overheating of the assembly during the process is physically excluded.

The temperature/time profile with a significantly longer peak temperature to simulate the upper load limit.

Tests are currently underway with other components from Würth Elektronik. This page will be updated accordingly as soon as the results are known.