Flex Solution PCBs

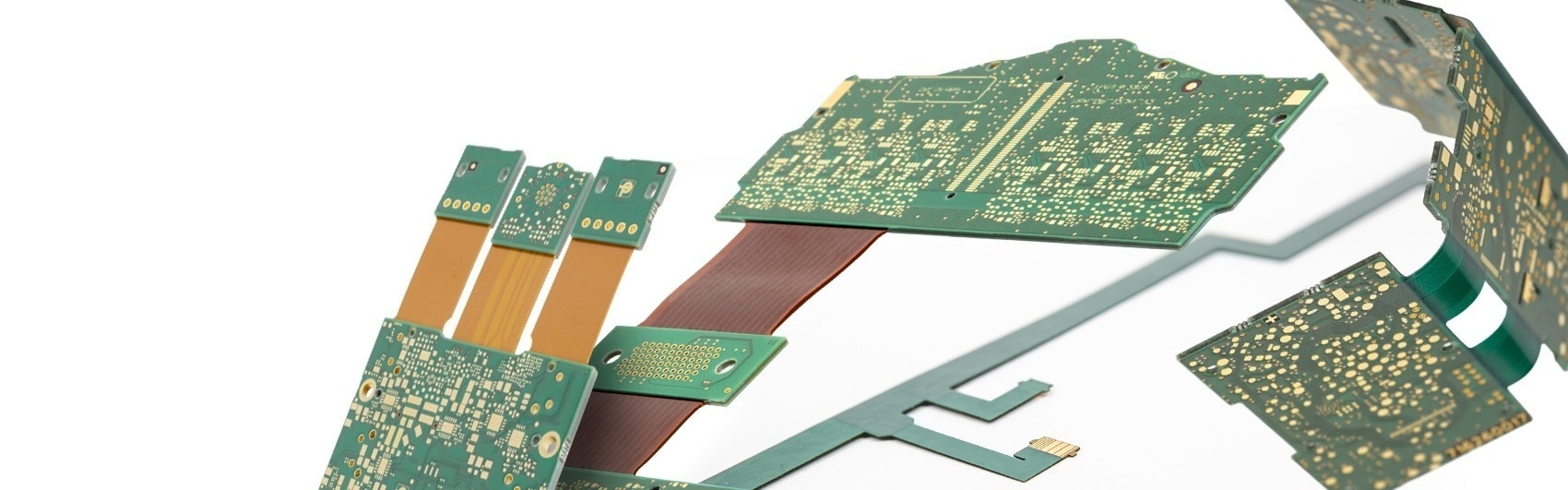

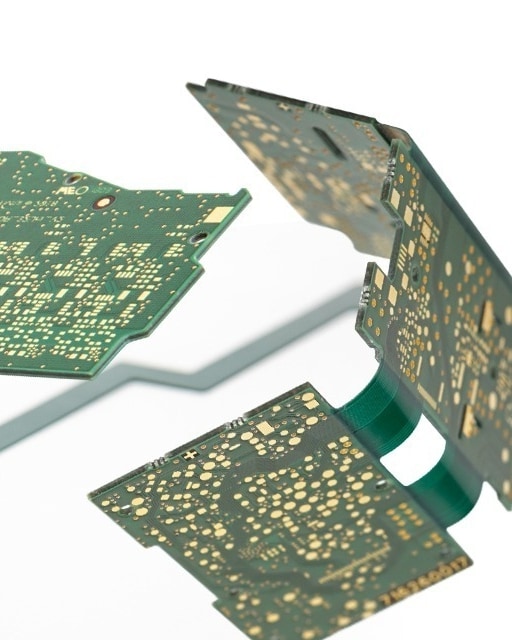

Efficient use of space thanks to flexible, rigid-flexible or bendable PCBs

The trend towards miniaturization in electronics continues unabated. Technically, it is therefore increasingly necessary to make efficient use of the ever smaller housings by means of mechatronic PCB solutions in all three dimensions.

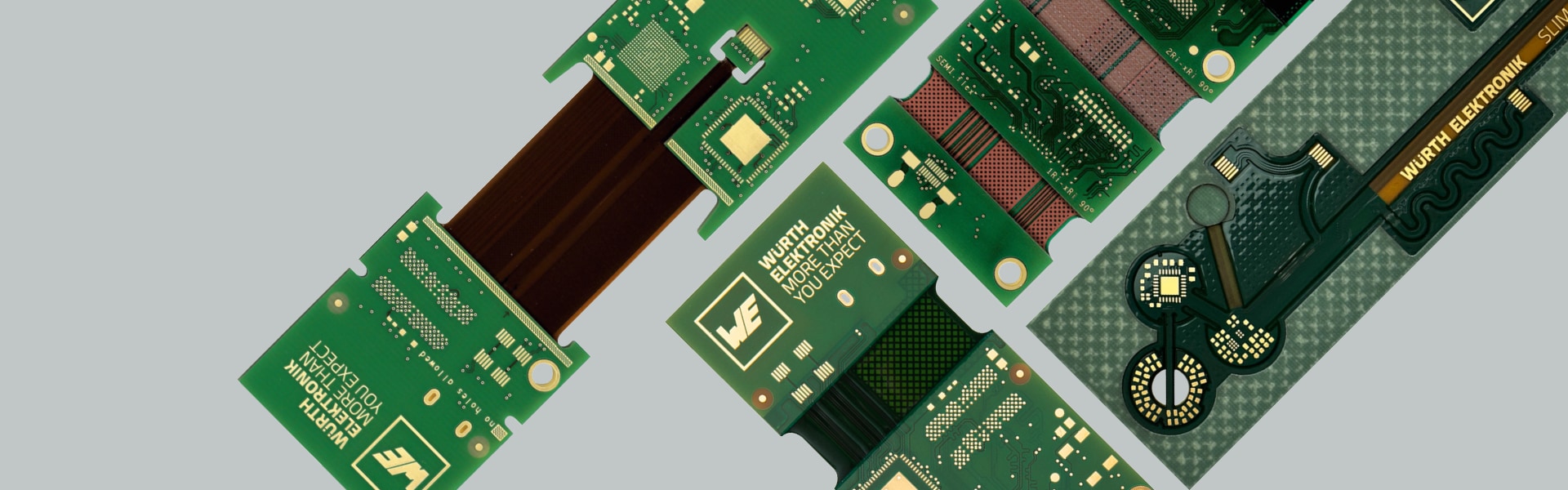

Whether PURE.flex with or without stiffener, SEMI.flex, RIGID.flex or SLIM.flex: Würth Elektronik offers you the right flex technology for your product. Through the use of special materials and the application of different structures, we work with you to develop the optimum solution for your task. And all this at an optimal cost-benefit ratio.

Our experienced product managers will advise and support you as early as the development phase of your product. Get in touch with us!

To give you an even better overview of our flexible PCB solutions, we now offer a practical sample pack containing all our flex technologies. This pack complements our existing range of individual samples and allows you to compare different flex technologies directly with each other – in a compact, clear, and practical way.

The Flex Solutions sample pack includes samples of the following technologies:

Whether for design decisions, technical evaluations, or customer presentations—with the sample package, you have the most important variants of our flexible solutions right at your fingertips.

Request your free sample package now and discover the possibilities of our flexible technologies!

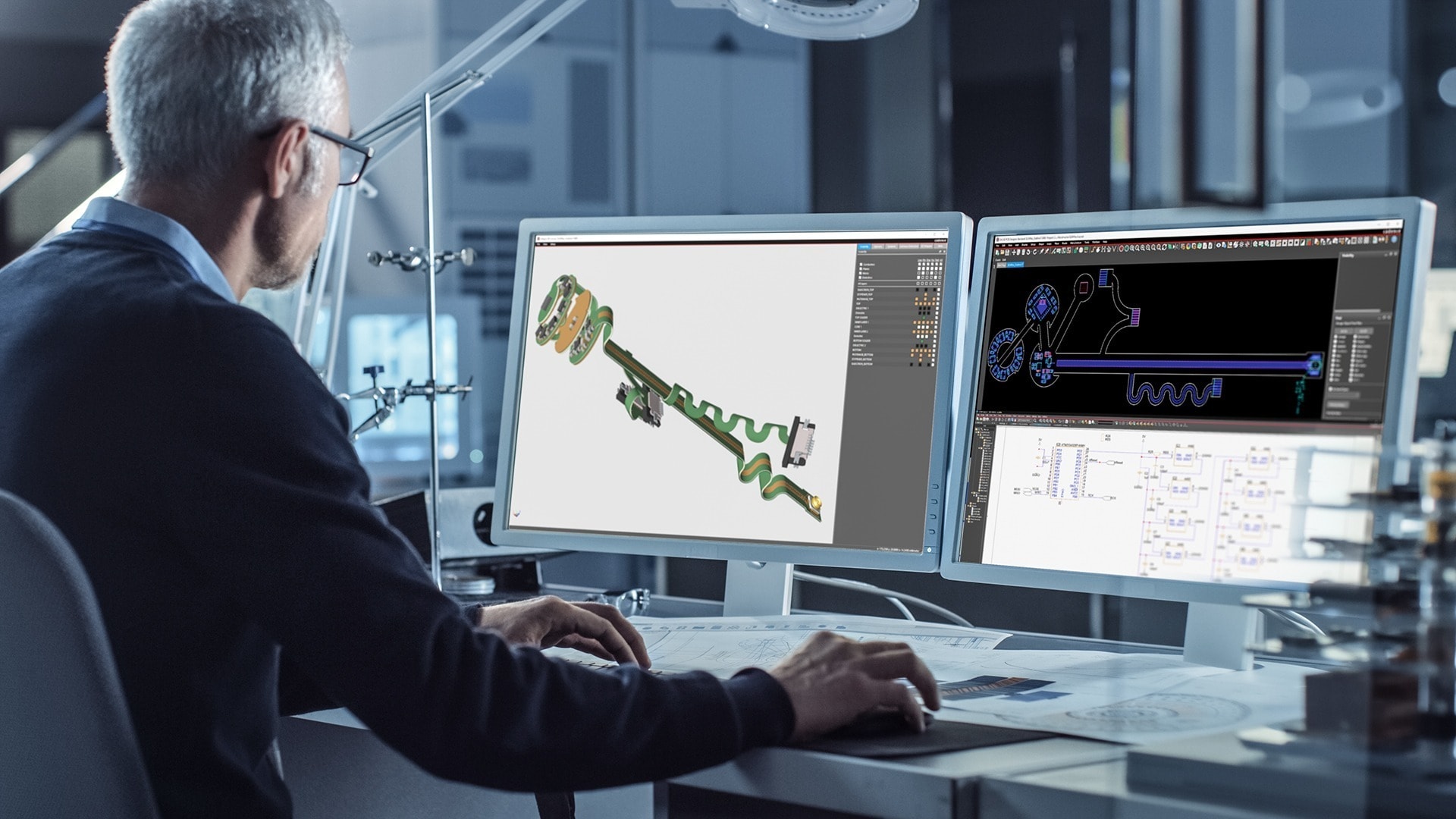

Relevant parameters for production-ready PCB design

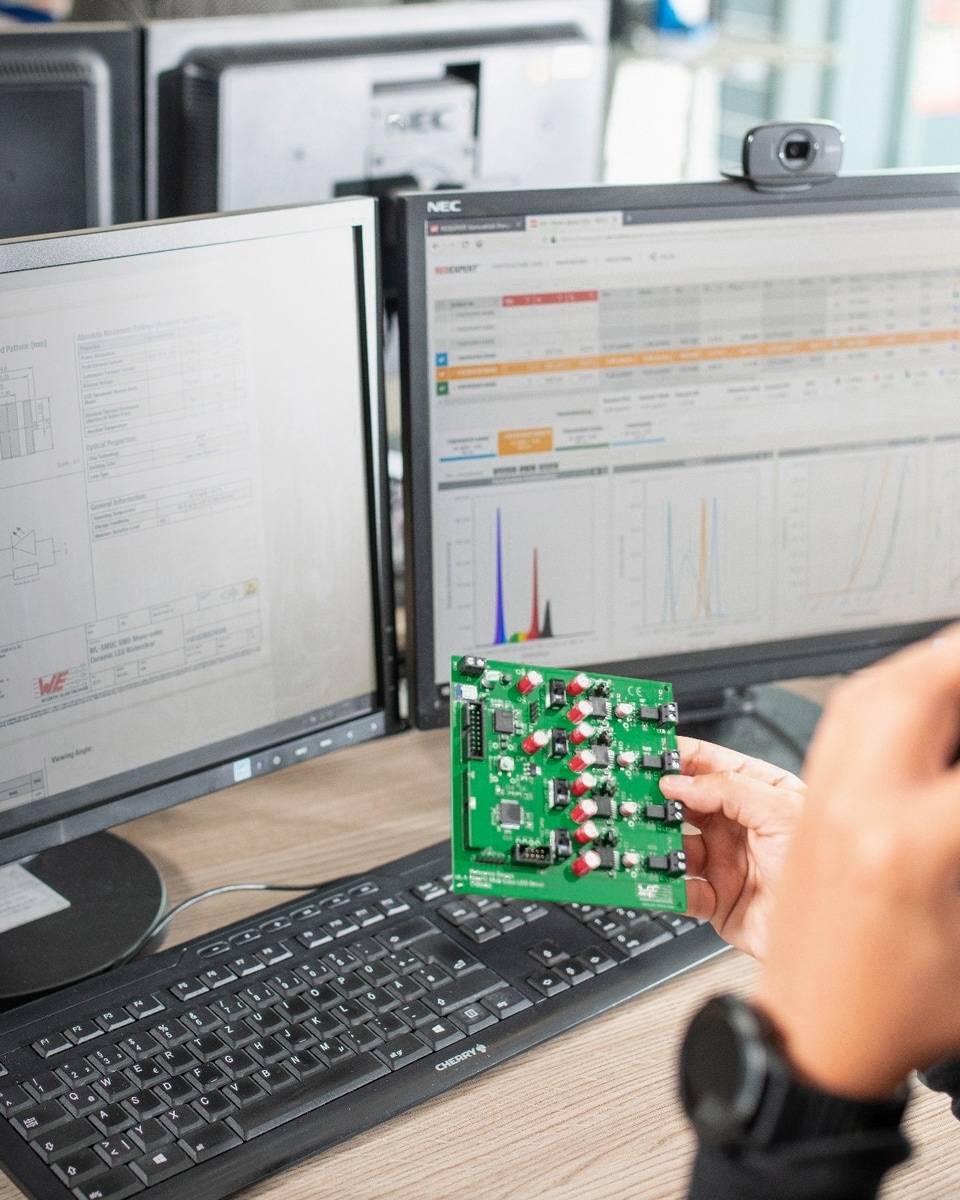

Modern printed circuit board solutions are more than just connecting elements. They are the key to progress in electronics. With this in mind, we actively support our customers in development and also offer our own system solutions with electronic functions.

In our design guide for flex solutions you will find an overview of all variants of our flex solutions. In addition, our specialists have summarized valuable design tips for you here. This will help you to bring your application to success, reliably and safely.

Applications that go beyond the standard require technical clarification with our product management. We will also be happy to support you with delivery panels for RIGID.flex solutions. Send us an email and we will be happy to deal with your questions immediately.

Would you like to download our design guides and design rules as a clear technology poster? The poster provides you with the most important information about efficient PCB design.

Flex solutions

Flex solutions

From purely flexible circuits to semi-flexible and rigid-flexible PCBs, the range of different technologies in the area of flex solutions extends. Through the use of special materials and the application of different structures, the right solution for your task can be worked out together. And this at an optimal cost-benefit ratio.

Flex and RIGID.flex PCBs are often designed with a ZIF interface (ZIF = Zero Insertion Force) and have a so-called ZIF contact for connecting a module via a detachable plug connection. There are different possibilities in the design and manufacture of a ZIF contact in PCB technology as an FPC solution (Flexible Printed Circuit). This in turn has an impact on many aspects such as connector selection and tolerances, on delivery array design and on costs.

Webinar recording 'Our flex solutions – how much flexibility do you need?'

Contact us