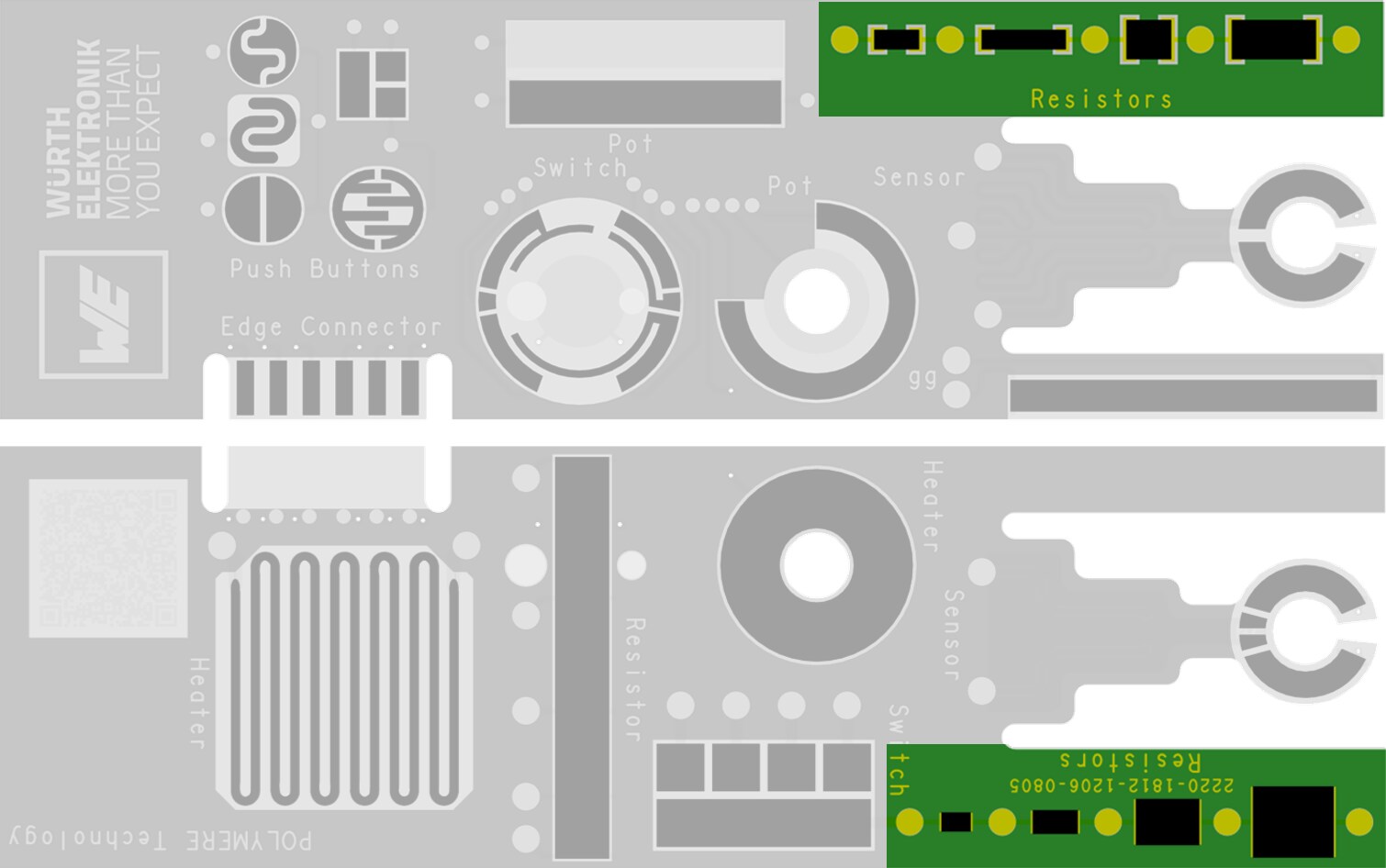

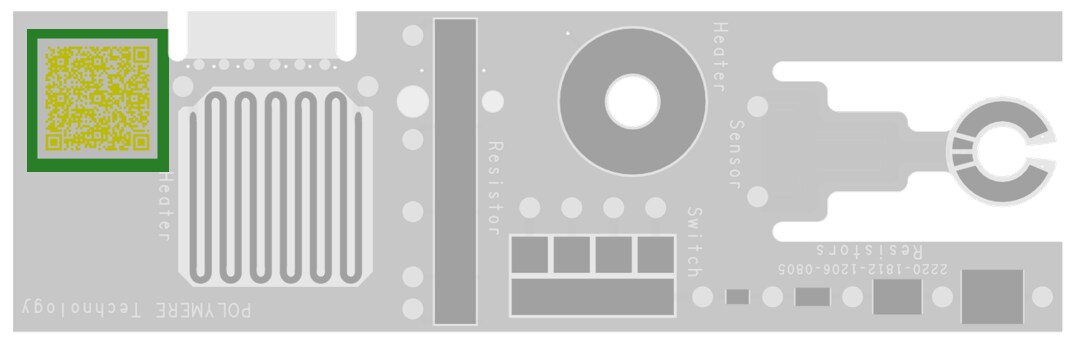

PRINTED.polymer Physical PCB Sample WE.polymer

Our physical PCB sample WE.polymer shows you different functions of PRINTED.polymer technology, from resistors to contacts, heaters and switches to sensors.

Electroless nickel/gold (ENIG) is used as the soldering surface.

The contour is milled.

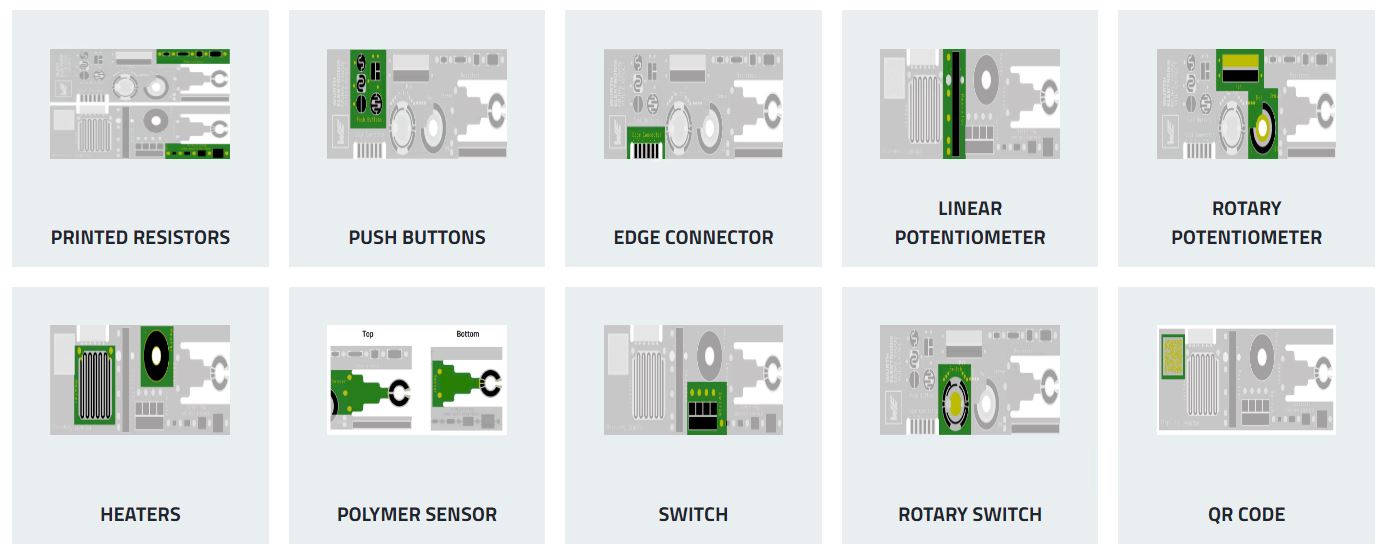

Design: The printed resistors are versatile over a resistance range from 10 ohms to 1 GigaOhm.

Explanations: Printed resistors are ideal for use as pull up/down and/or terminating resistors. Tolerances are <+/- 30% untrimmed, tolerances of +/- 5% can be achieved using laser trimming. With voltage dividers, a divider ratio of < 3% can be achieved.

The resistors can be printed on inner and outer layers.

Description: Keypad contacts are actuated via switching mats or contact springs.

Two contact surfaces with different potentials are short-circuited.

Explanations: The printing serves as passivation and ensures a uniform contact resistance over the entire service life.

Contact resistance is influenced by the mating contact and contact pressure, is usually < 20 ohms. Several million touch strokes are possible without problems, tested in cell phones before the touchscreen generation.

Description: Due to the abrasion resistance of the polymer print and resistance to environmental influences, polymer pastes are also suitable as edge connectors. They are more robust than a version in ENIG and cheaper than electroplated gold.

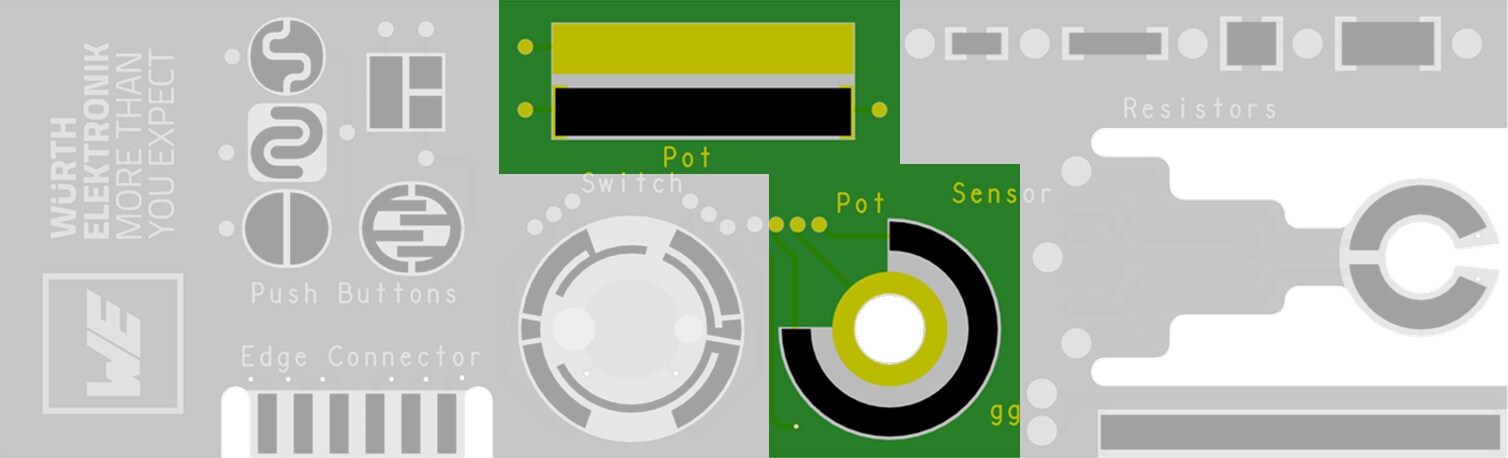

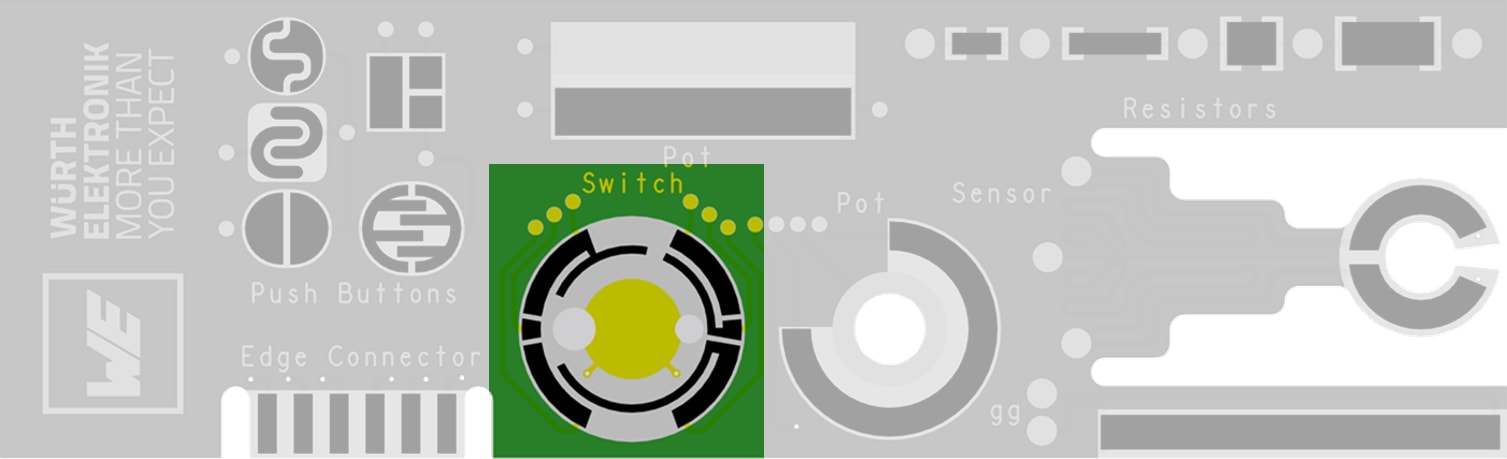

Description: Potentiometers can be made very easily with a combination of resistive printing and a slider.

Explanation: Depending on the design, linear or logarithmic resistance characteristics are possible.

Design: With a combination of resistance printing and a slider, it is very easy to produce sliding and rotary potentiometers.

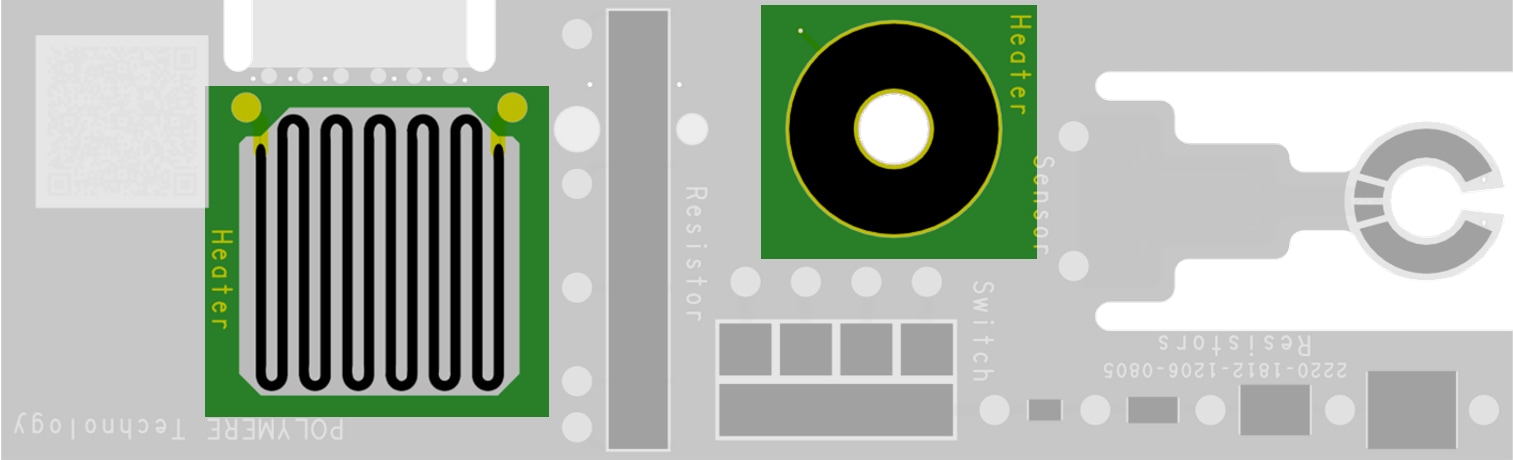

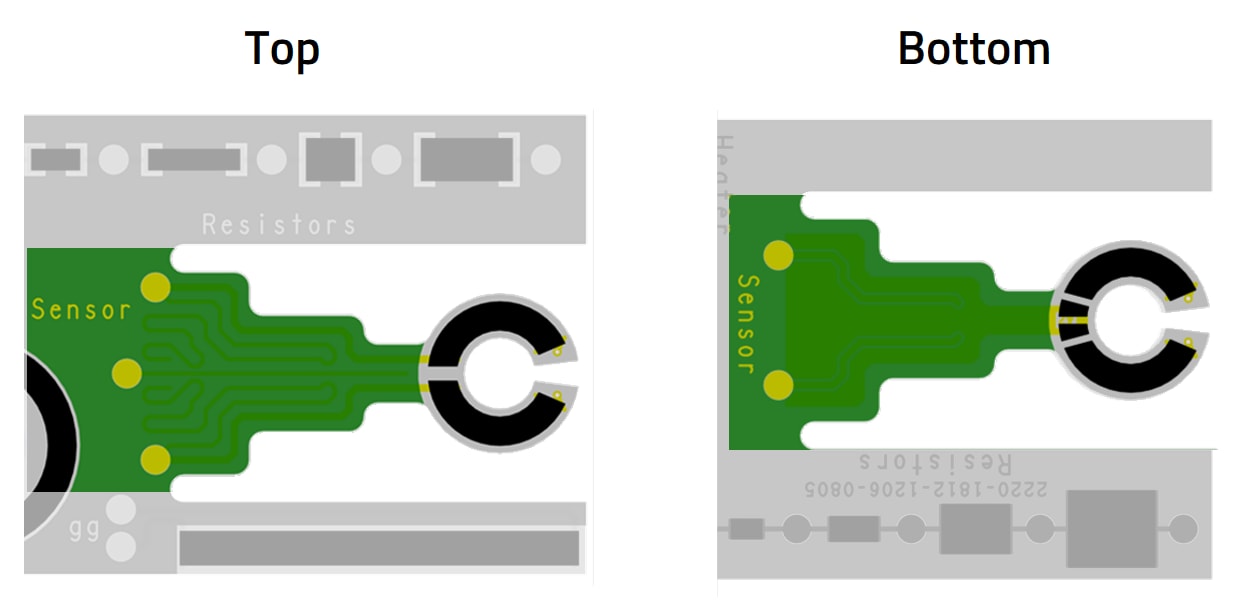

Description: With the large contact area, the power dissipation at a printed polymer resistor can be realized specifically as a heater on a PCB basis. Due to the polymer properties, the heaters are self-regulating and do not require control via a microcontroller.

Description: Due to the physical properties of the PRINTED.polymer pastes, various sensors can be realized. For example, a strain gauge or a temperature sensor.

Explanation: You have an idea ? please contact us!

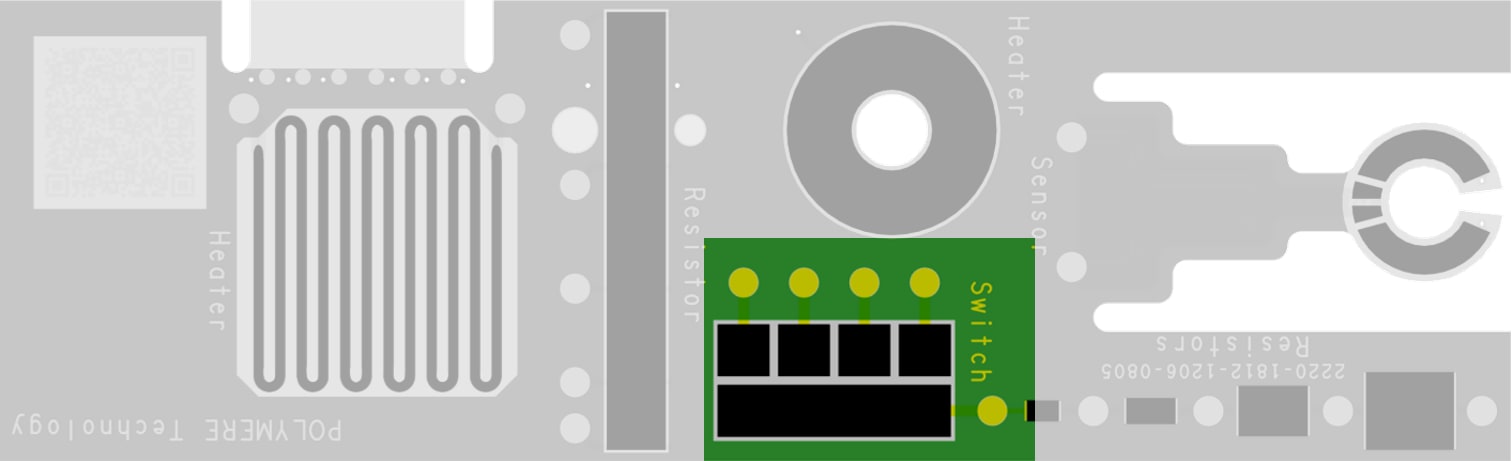

Description: switches are actuated via sliding contacts, whereby contact surfaces with different with different potentials are closed.

Explanations: The polymer printing ensures uniform contact resistance throughout the entire service life. The contact resistance is influenced by the mating contact and the contact pressure and is < 20 ohms. More than 200,000 switching cycles are achievable with standard sliders.

Description: Switches are actuated via sliding contacts, whereby contact surfaces with different with different potentials are closed.

Explanations: The polymer printing ensures uniform contact resistance throughout the entire service life. The contact resistance is influenced by the mating contact and the contact pressure and is < 20 ohms. More than 200,000 switching cycles are achievable with standard sliders.

Design: link to this page via www.we-online.com/polymersample