Thermal Management

Increasing requirements

There is a steady advancement in the performance, miniaturization and integration density of semiconductors. As a result, the heat dissipation of components and devices is becoming more and more important.

Not only are the requirements for electromagnetic compatibility (EMC) increasing, but a concept for thermal management must also be developed. Both the power dissipation of components is increasing rapidly and the density within an assembly is growing strongly. Rising clock frequencies and increasing packing density on the silicon chip, in the package and on the printed circuit board are causes for the constantly increasing heat. The development of semiconductor circuits with minimized power dissipation can only marginally counteract this trend.

Together with you, we develop clever thermal management concepts that directly dissipate heat through constructive measures at PCB level. In this way, high-performance components and LEDs are economically protected from excessive temperatures and a flawless function as well as long service life are guaranteed.

Advantages of Würth Elektronik Thermal Management

Wide range of applications

Relevant parameters for production-ready PCB design

Modern printed circuit board solutions are more than just connecting elements. They are the key to progress in electronics. With this in mind, we actively support our customers in development and also offer our own system solutions with electronic.

The Thermal Management design rules include all the important parameters you need to make your project successful:

Would you like to download our design guides and design rules as a clear technology poster? The poster provides you with the most important information about efficient PCB design.

Improved heat dissipation in comparison to FR4

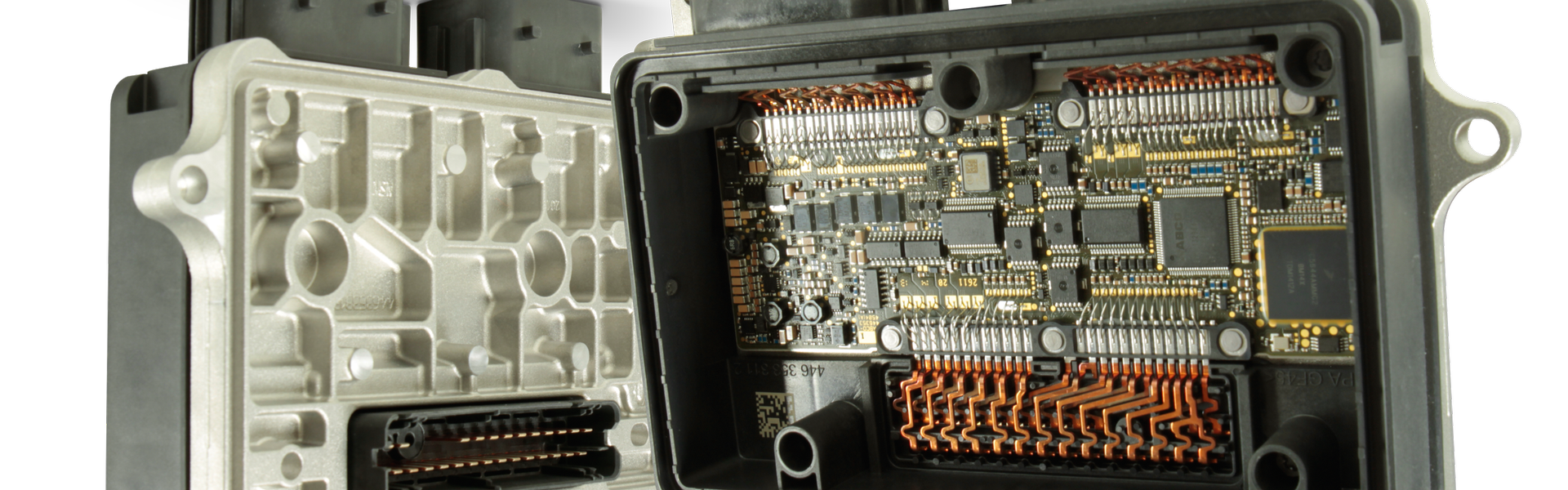

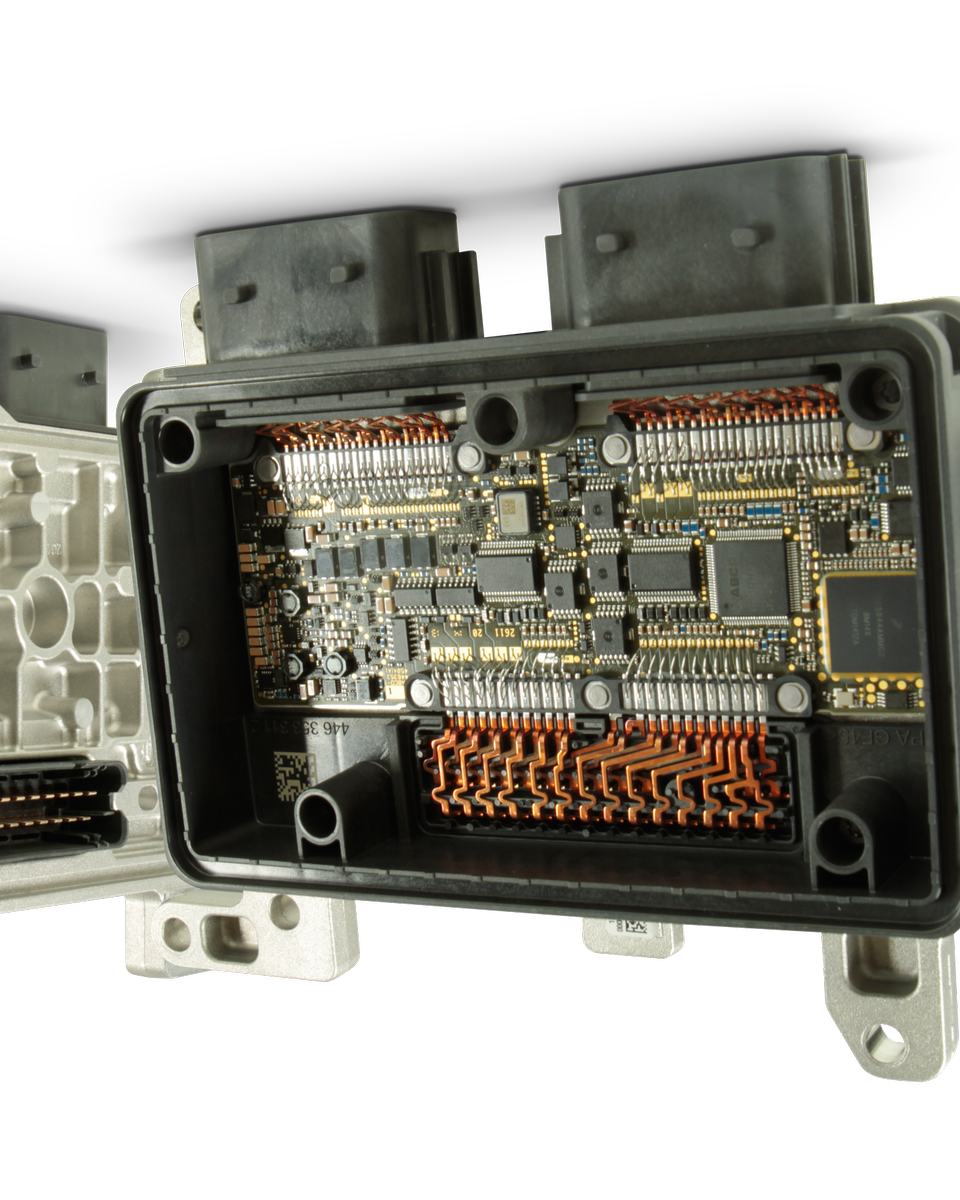

A special but very effective way of dissipating heat from components via the printed circuit board is to use IMS printed circuit boards for simple single-layer circuits. These are usually constructed from aluminum carrier, insulation layer and copper foil, whereby the base materials are available in different construction variants.

The heat generated from components such as LEDs and transistors can be easily spread and passed on. The thermal conductivity value of the insulation layers used between the copper layer and the metal carrier is 5 to 10 times higher compared to conventional FR4 materials.

For more information, please see our IMS Thermal Management Design Rules.

Dissipate heat electrically safely insulated

Coverlay, a composite material made of polyimide film and adhesive, can be bonded to specific areas of a printed circuit board as insulation. In this way, high dielectric strength can be achieved.

You can find out here which design rules need to be observed.

Would you like to learn more about the use of Coverlay as insulation film?

Then watch the recording and presentation of our webinar "Coverlay - more than a flexible solder resist replacement" here:

PCB thermal management

Learn more about our technologies and services. In this video tutorial, our PCB experts explain the possibilities of intelligent thermal management on a PCB basis and which PCB design goals can be achieved by it.

This video tutorial is an excerpt from our webinar "HDI Microvia - High Performance PCB System Moves the Masses" and is also available as a presentation.

Contact us