WE SYSTEMS is not affected by the plant closure in Schopfheim. We are still there for you as usual!

WE systems

... the first choice for customized wire bonding services and printed circuit boards

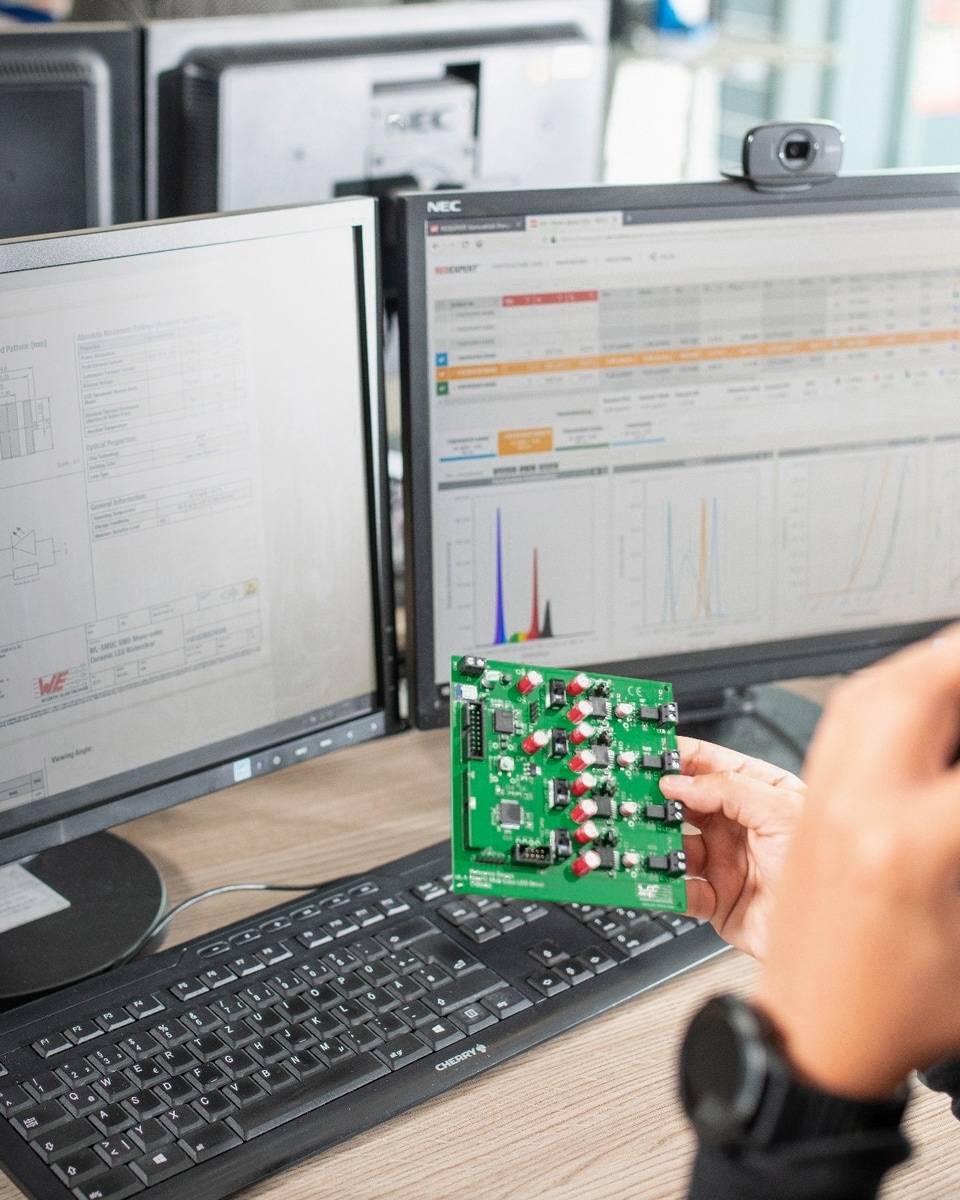

We provide you with a combination of wire bonding services, PCB and processing of customized systems

Wire bonding is the basic technology in which micro-welding is used to create an electrical connection between the chip contact surfaces (pads) and the chip carrier or substrate via micro-wires. This process is also known as chip-on-board (COB). A complete COB process includes die bonding, wire bonding and the protection of the bare chip with a suitable encapsulant. We have experience with all common surfaces and numerous tests have proven the high reliability of our assembly and bonding techniques.

We provide you with the right combination of wire bonding service and PCB - from a single source. We would be happy to provide you with a customized offer.

Are you looking for a partner for services “outside the PCB”?

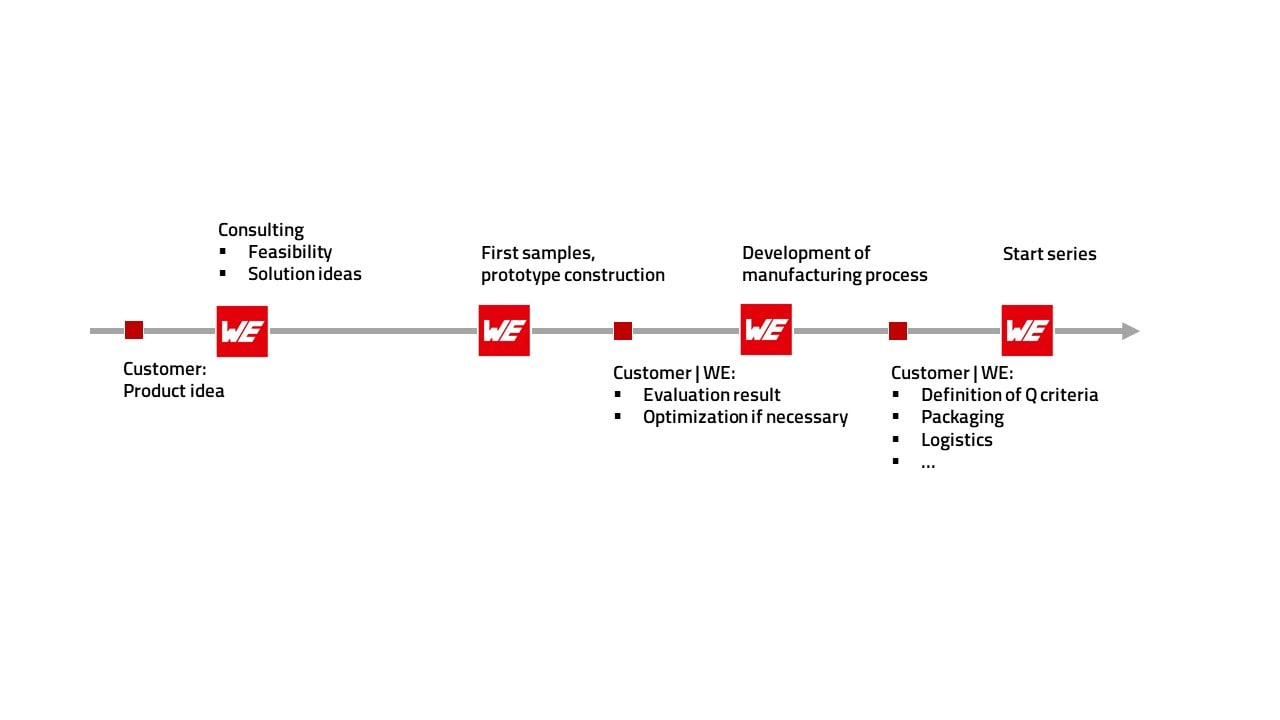

Would you like to concentrate on your core business and need a professional service provider to take care of production from prototype to small and large series?

Then you've come to the right place as a system provider!

materials and assembly of the end product

Please feel free to contact us.

"WEsystems - Bonding and more"

Die bonding on printed circuit boards? And wire bonding? Or the complete manufacturing process for the production of the module or the entire electronic assembly from the PCB to the end product?

True to the motto “more than you expect” and “everything from a single source”, WEsystems, as part of Würth Elektronik Circuit Board Technology, offers the right combination of wire bonding services and PCBs.

Watch the recording of our webinar to learn about the processes and services for customized systems and find out more about:

Fully automatic precision loading

Precision chip setting

We are your partner for various joining techniques:

We assemble different materials, housing parts and printed circuit boards into complete modules according to your specifications. On request, we can also take care of the complete assembly right through to the final product ready for delivery.

Our know-how and modern machinery guarantee the best results. This also includes special machines for customer-specific requirements.

Get in touch with us directly!

The end result of the process is your success

As customer experts and your solution provider, we offer comprehensive advice - our knowledge for your success!

Contact us