Is the Space for a Chip on Your PCB Limited?

Wire bonding is the basic technology in which an electrical connection between the chip contact surfaces (pads) and the chip carrier or substrate is established by the micro-welding of micro-wires. The latter is also called chip-on-board (COB). A complete COB process includes chip bonding, wire bonding and protection of the bare chip by a suitable encapsulant.

We have experience with all common surfaces. Numerous tests have already proven the high reliability of the assembly and connection techniques.

We provide you with the appropriate combination of wire bonding service and printed circuit board - all from one source. We would be pleased to submit you an individual offer.

Advantages of Würth Elektronik Wire Bonding Technology

Relevant Parameters for Production-ready PCB Design

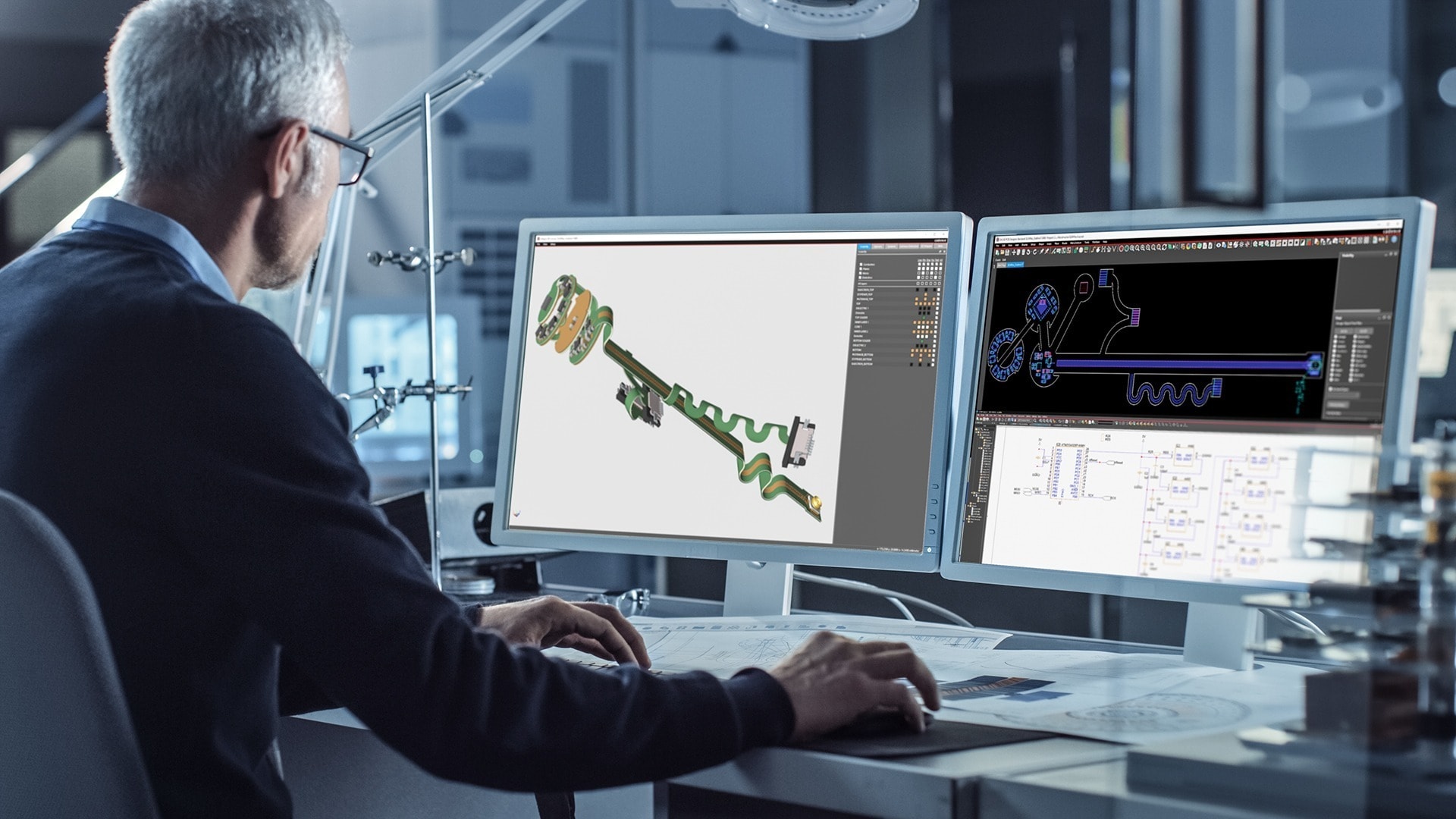

Modern printed circuit board solutions are more than just connecting elements. They are the key to progress in electronics. With this in mind, we actively support our customers in development and also offer our own system solutions with electronic

The Wire Bonding Design Rules include all the important parameters you need to make your project successful:

In the Following Video, We Show You Why Würth Elektronik Wire Bonding Technology Is an Excellent Way to Bond Chip and PCB Substrate.

The cost difference between assemblies with housed, soldered components on the one hand and wire-bonded bare dies on the other depends on several factors. For example, the number of connections plays a role, as do the distances involved in wire bonding.

In general, wire bonding has a cost advantage for smaller and medium quantities. We will be happy to determine the costs individually for your wire bonding project.

Both processes cost about the same at Würth Elektronik. The only difference is the slightly more expensive ENEPIG surface for gold wire bonding, compared to the ENIG surface for aluminum wire bonding.

This depends on the process and must be checked individually for larger distances of more than approx. 5 mm.

Yes, we regularly process flexible printed circuit boards for series products in high volumes.

There is no minimum order quantity.