The central feature of aluminium-polymer capacitors is that a conductive polymer is used instead of a liquid electrolyte (e.g. classic electrolytic capacitors). Aluminum polymer and aluminum electrolytic capacitors have very good behavior against the effects of voltage and temperature, while aluminum polymer capacitors also have a very positive characteristic with respect to the subject of aging. These capacitors are also extremely interesting in terms of price as soon as the capacitance in the application has to be increased. In addition, the special design process can significantly reduce the parasitic effects (here especially the ESL). This means for the application that a high ripple current, low parasitic inductances, high reliability and very good temperature properties are possible.

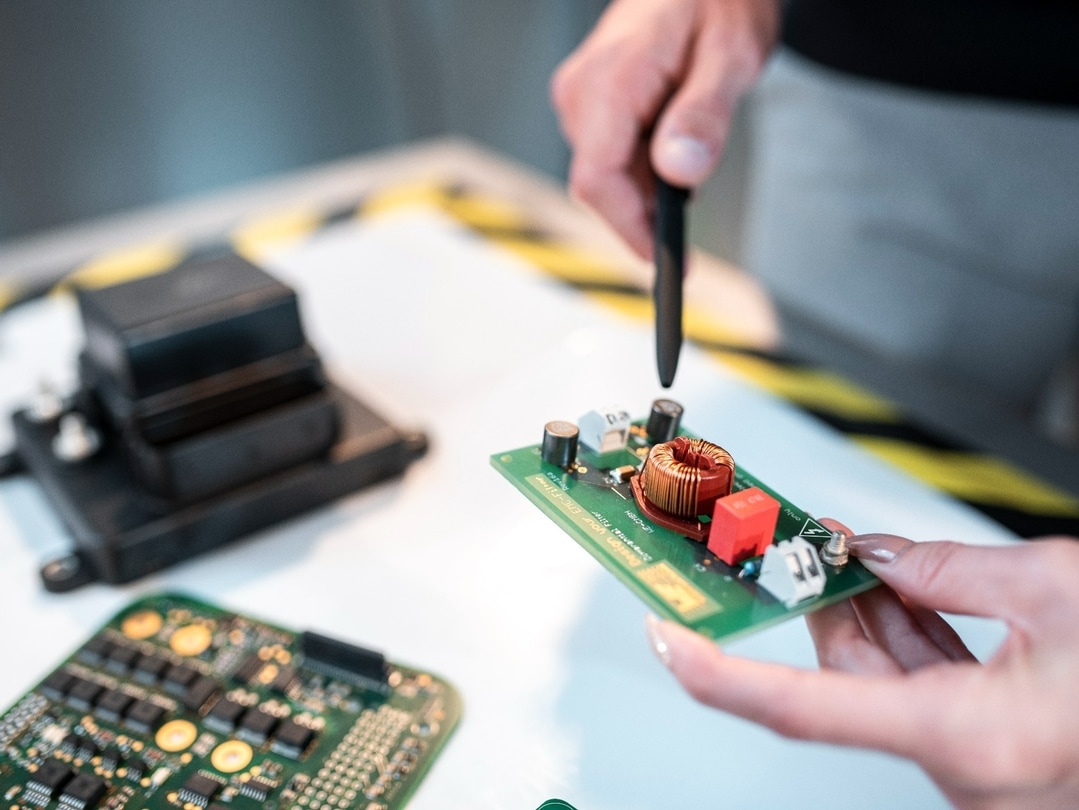

With Würth Elektronik eiSos, the capacitance values of aluminum polymer capacitors range from 10 µF to 2 mF at a voltage range of 6.3 V to 100 V in a wide variety of packages. Due to the very good electrical properties, the possibilities of use are very wide and range from classic back-up solutions of voltages, buffering of the supply voltage (of ICs), via bypass or decoupling of signals, filter applications to voltage smoothing of switching regulator applications. In this AppNote the application of aluminum-polymer capacitors in the field of filtering and voltage smoothing is described.

Download: ANP071