Cost-effective alternatives

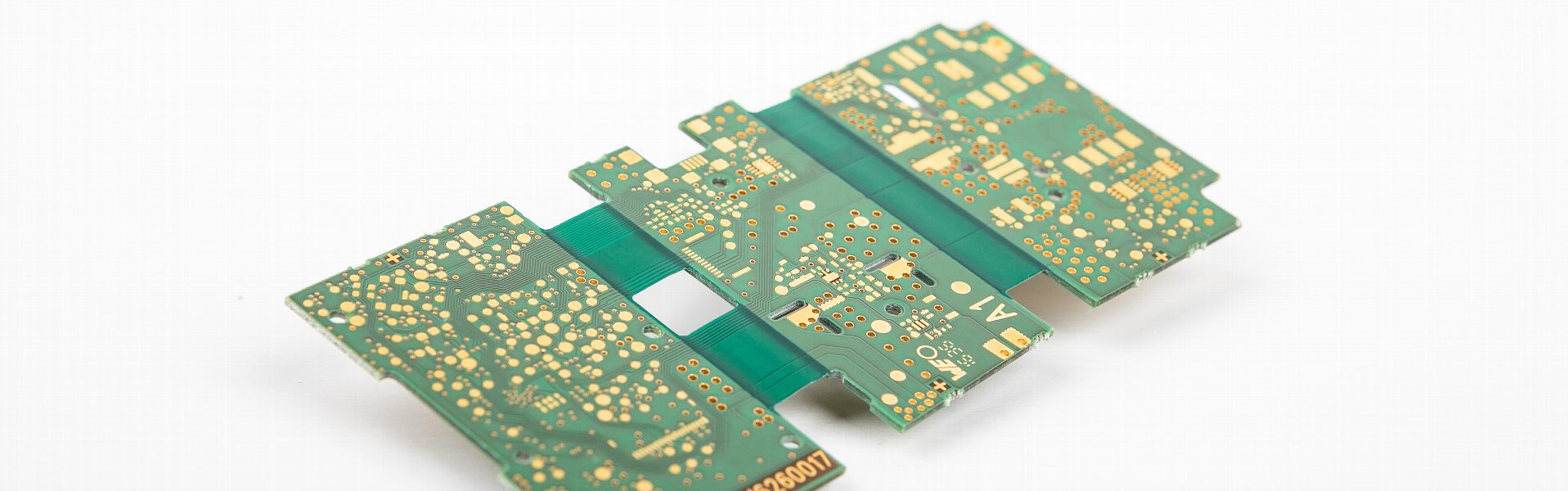

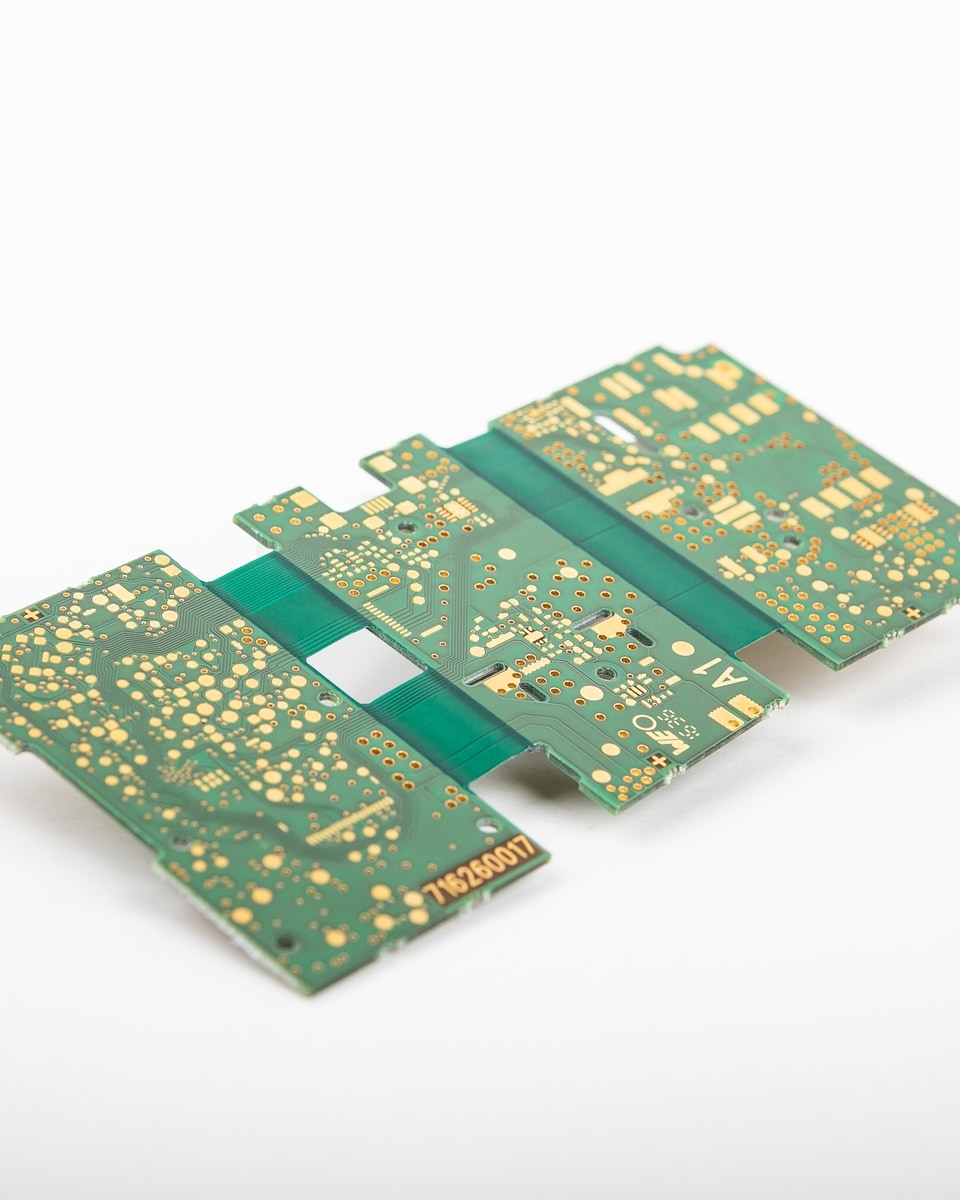

Rigid base material such as FR4 is bendable if it becomes sufficiently thin. If an application requires only a few bends with a large bending radius for installation in a statically clearly defined housing, SEMI.flex technology can be a cost-effective alternative to RIGID.flex. The thin bending areas can be created by a precise depth milling process. This technology has been in series use for many years, including in automotive applications.

A more efficient variant is the BEND.flex technology. It has thin bending areas formed by thin cores similar to those of RIGID.flex technology, but without using flexible films made of polyimide.

For clarification of the design and application possibilities, advice should be sought at this point from the PCB manufacturer you trust.

Advantages of Würth Elektronik SEMI.flex technology

Relevant parameters for production-ready PCB design

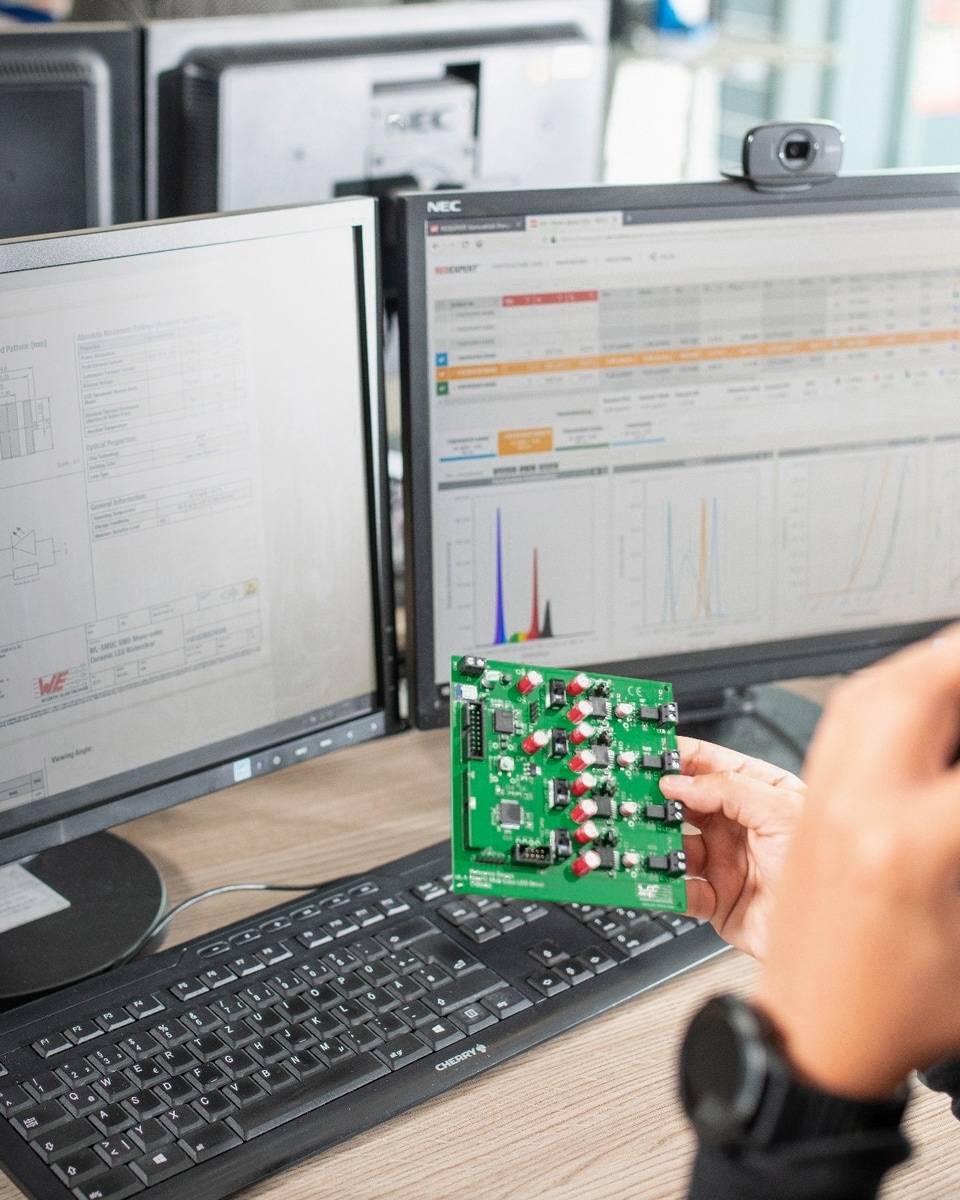

Modern printed circuit board solutions are more than just connecting elements. They are the key to progress in electronics. With this in mind, we actively support our customers in development and also offer our own system solutions with electronic functions.

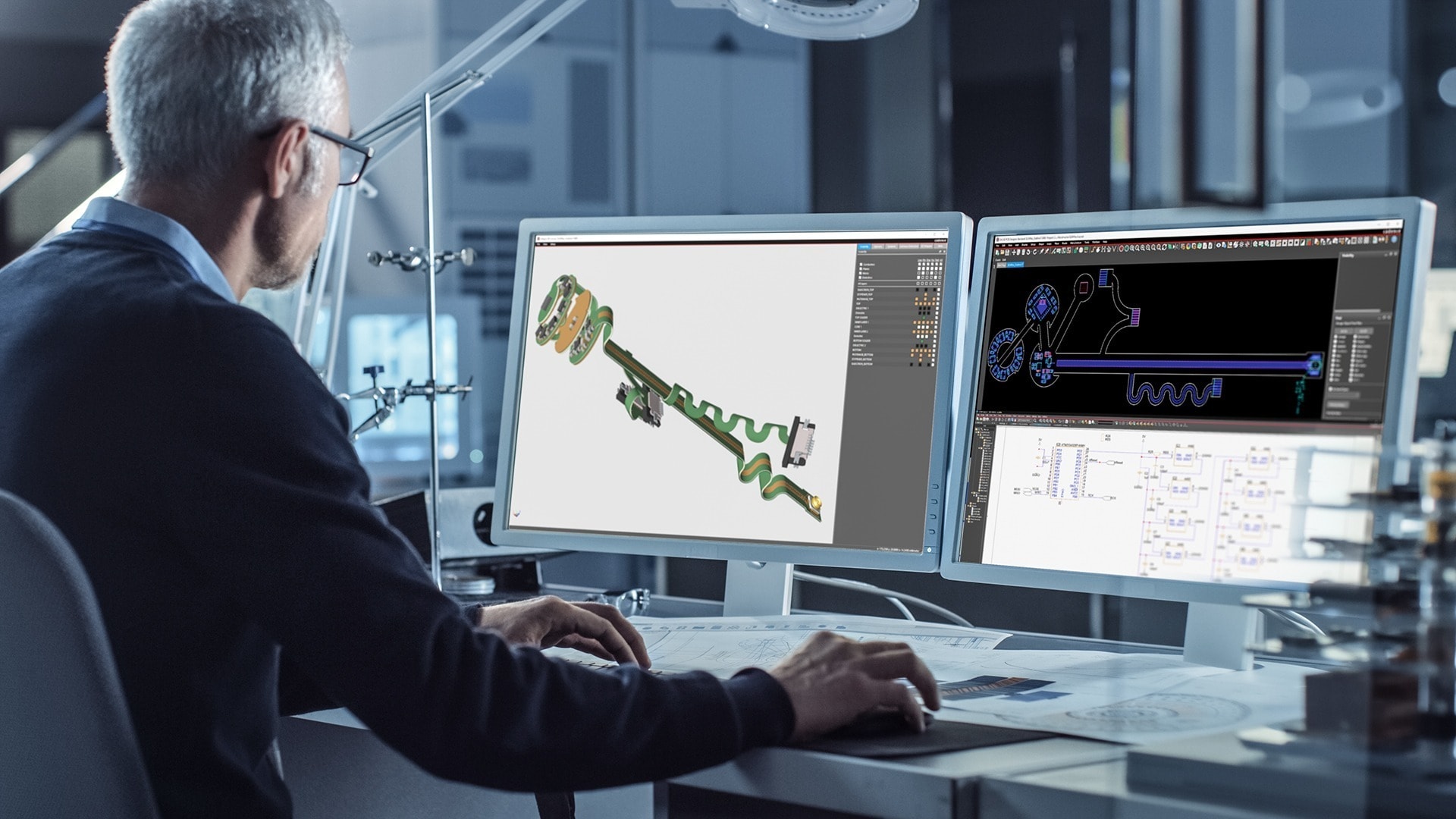

The SEMI.flex design rules include all the important parameters you need to make your project successful:

In our design guide you will find an overview of all variants of our flex solutions. In addition, our specialists have summarized valuable design tips for you here. This will help you bring your application to success reliably and safely.

"SEMI.flex - an award-winning miniaturization success"

Compact and powerful - these features increasingly characterize the requirements for new electronic systems. The foundation for the success of the product is already laid in the concept and idea phase. Learn in this webinar which advantages designing your PCBs according to Würth Elektronik design parameters offers you.

More SEMI.flex webinars:

"Putting an end to cable clutter - Wiring 4.0 via SEMI.flex in practice"

Webinar "SEMI.flex - an award-winning miniaturization success"

We open up technological opportunities for our customers

Using Würth Elektronik's SEMI.flex technology can save a lot of time and thus costs in PCB design. Find out in this success story how the joint project team of Metz and Würth Elektronik successfully mastered the challenges of the project.

More than SEMI.flex

BEND.flex takes an intermediate position between SEMI.flex and RIGID.flex, both in terms of price and bending performance. As a result, more options are available.

With the BEND.flex technology in a valve electronics, the world's first app-controlled valve was achieved. Find out in this success story how the joint project team of Festo and Würth Elektronik successfully mastered the challenges of the project.

"Cost-efficient flexibility: Physical PCB sample WE.bend"

WE.flex again! In the third round of our webinar series, we present the new WE.bend hand sample. This combines the SEMI.flex and BEND.flex technologies and thus enables a direct comparison in the production and application possibilities of flexible printed circuit boards.

Content of the recording of the webinar on November 6, 2024:

This recording is ideal for PCB designers, developers and students who want to learn about innovative approaches in PCB technology.

Webinar "Cost-efficient flexibility: Physical PCB sample WE.bend"

Contact us