Wave Soldering is the process of soldering through hole components onto a PCB by passing the exposed contacts of the components placed on a board over a wave of tin molten solder. The solder wave flows under the PCB board and applies by capillarity solder to the contacts of components placed on the PCB board. It is primarily used to solder through hole connectors on printed circuit boards.

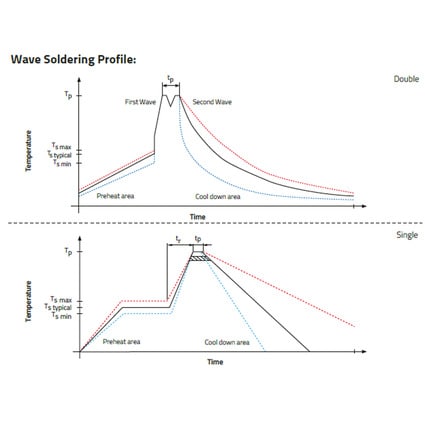

These two recommended wave soldering profiles are available for information purposes only. Please consider plastic material, circuit board features, connectors ranges and other technical properties when choosing your soldering parameters / a suitable soldering profile.