Applications

- High current Wire-to-Board connections up to 250 A

- Mounting of copper bars on PCBs

- Installation of laminated fuses

- Installation of IGBT modules

- Suitable for rough environmental condition

Application Notes

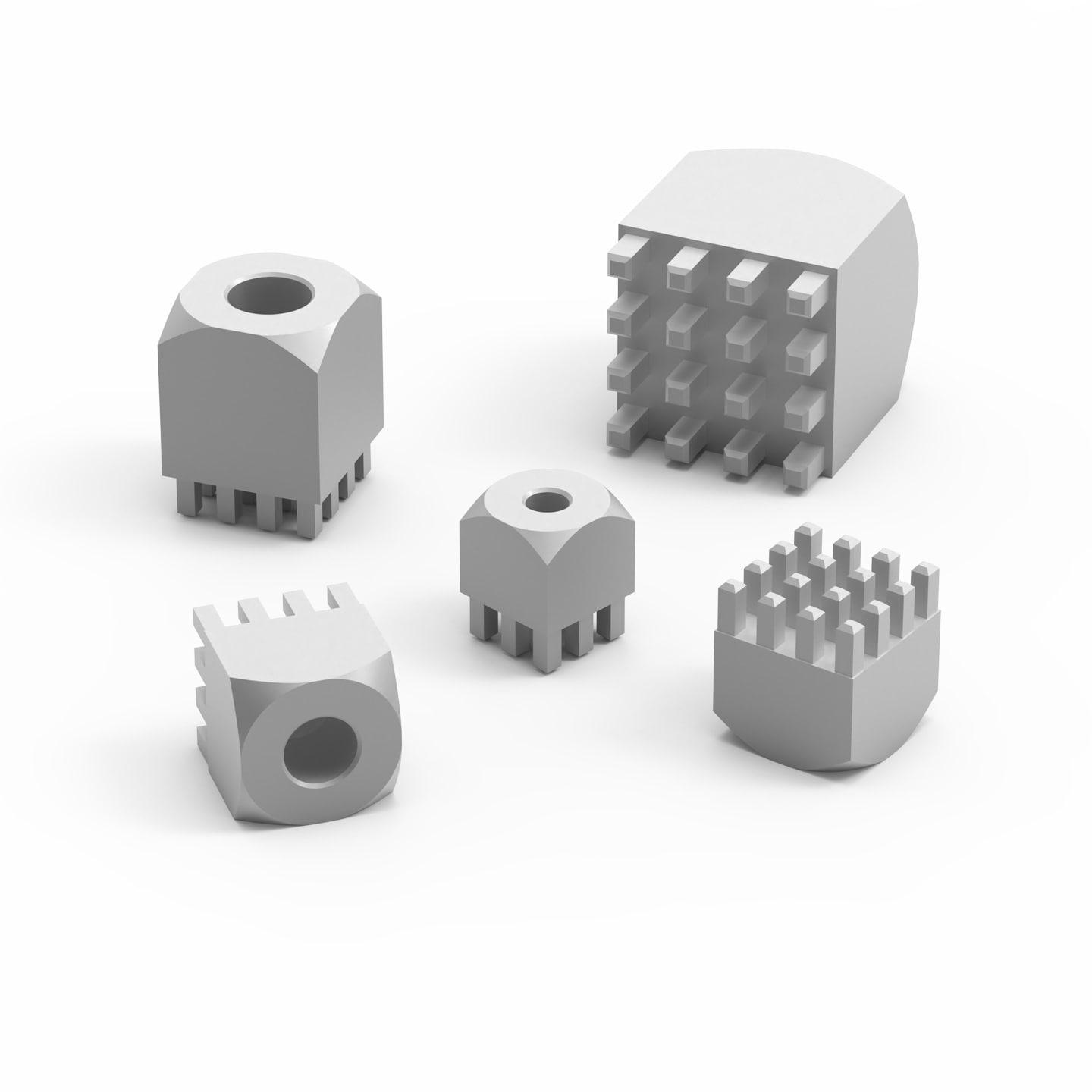

Products

| Order Code | Datasheet | Downloads | Status | W (mm) | H (mm) | IR (A) | Ti | Tl (mm) | Pins (pcs) | Samples |

|---|---|---|---|---|---|---|---|---|---|---|

| 786202073 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 7 | 9 | 130 | M3 | 3.5 | 9 | |

| 786202094 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 9 | 10 | 180 | M4 | 4 | 16 | |

| 786202095 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 9 | 10 | 180 | M5 | 4 | 16 | |

| 786202106 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 10 | 13.5 | 180 | M6 | 6 | 16 | |

| 786202148 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 14 | 16.5 | 250 | M8 | 8 | 16 |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | W (mm) | H (mm) | IR (A) | Ti | Tl (mm) | Pins (pcs) | Samples |

|---|