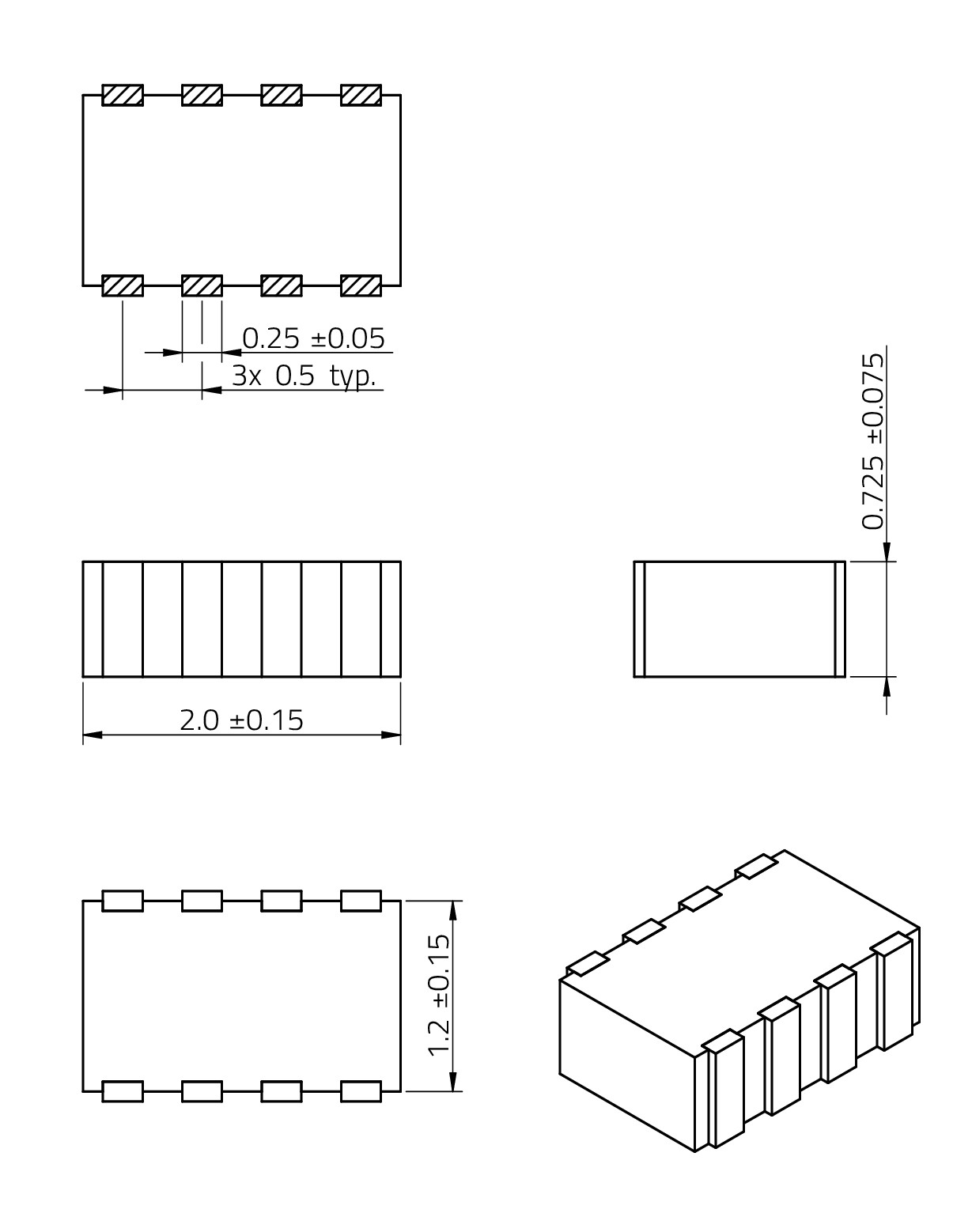

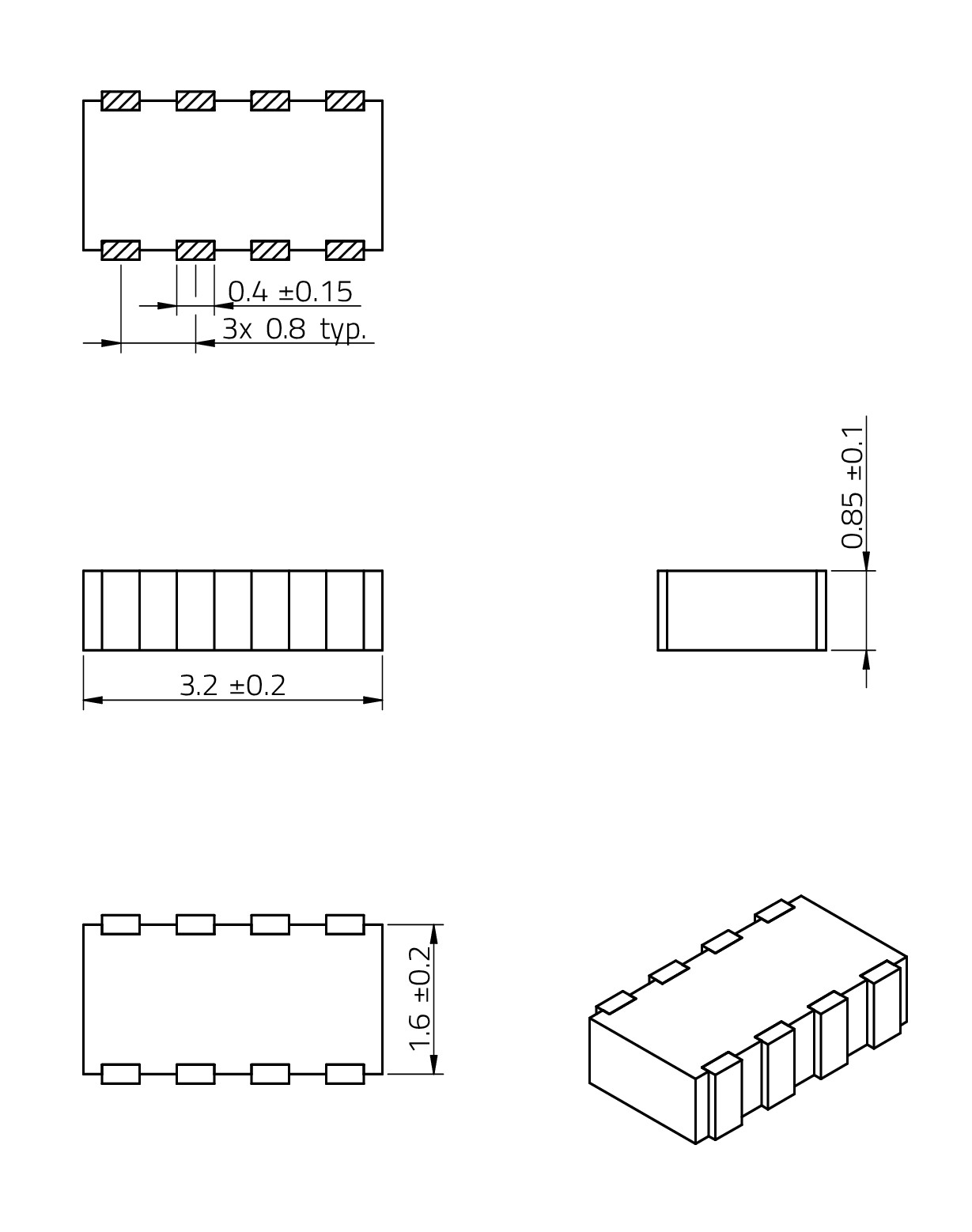

| Size | Dimensions | L (mm) | W (mm) | H (mm) | Fl (mm) | Mount | |

|---|---|---|---|---|---|---|---|

| 0508 | 2 | 1.2 | 0.725 | 0.25 | SMT | ||

| 0612 | 3.2 | 1.6 | 0.85 | 0.4 | SMT |

LTSpice files

Characteristics

- Fast response time (1 ns)

- Low signal insertion loss

- No leakage current

- Low clamping voltage

- Almost no energy consumption in stand-by mode

- Excellent absorption for ESD-impulses

- Operating temperature: –40 ºC to +85 ºC

Applications

- Protection of data lines

- Protection of bus systems

- Protection of video transmission lines

- Protection of semiconductors

- ESD protection in accordance with EN 61000-4-2

Application Notes

Products

All

0508

0612

| Order Code | Datasheet | Downloads | Status | Channels | CCh typ. (pF) | VESD Contact (kV) | Size | Application | Samples |

|---|---|---|---|---|---|---|---|---|---|

| 82380050100 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 4 | 10 | 8 | 0508 | Datalines, analog signals | |

| 82380180121 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 4 | 120 | 8 | 0612 | RS-232, Sensors |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | Channels | CCh typ. (pF) | VESD Contact (kV) | Size | Application | Samples |

|---|

Videos

Würth Elektronik Webinar: Effective ESD protection with TVS diodes