Applications

- High current Wire-to-Board connections up to 500 A

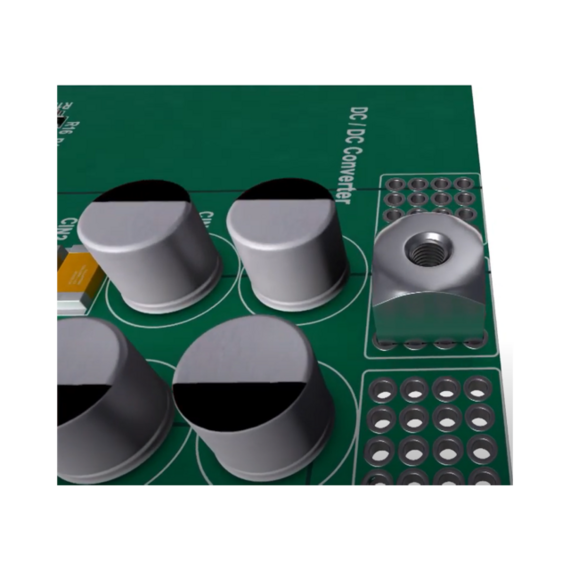

- Mounting of copper bars on PCBs

- Installation of laminated fuses

- Suitable for rough environmental conditions

| General Information | |

|---|---|

| Operating Temperature | -55 °C up to +150 °C |

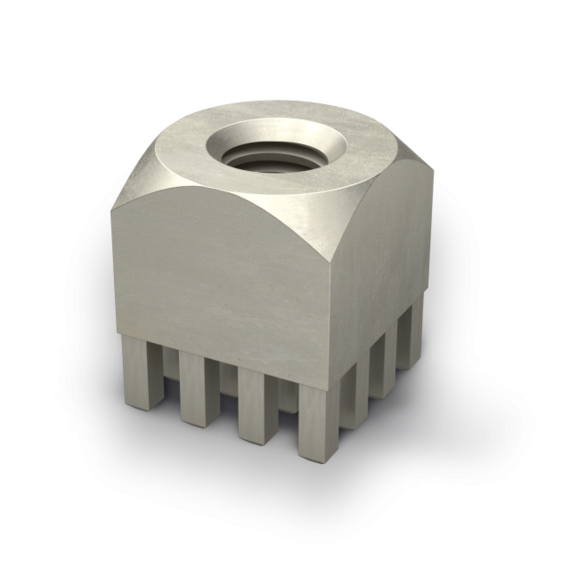

| Material | Brass |

| Surface | Tin |

| Execution | Press-Fit |

| Packaging Properties | |

|---|---|

| Packaging | Bulk; Tray |

Application Notes

Products

| Order Code | Datasheet | Downloads | Status | W (mm) | H (mm) | IR (A) | Ti | Tl (mm) | Pins (pcs) | Design Kit | Samples | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7461148 | SPEC | 7 files | Active i| Production is active. Expected lifetime: >10 years. | 7 | 6 | 130 | M2.5 | 6 | 8 | – | |

| 7461086 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 9 | 6 | 175 | M4 | 6 | 12 | 746701 | |

| 7460408 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 9 | 6 | 175 | M5 | 6 | 12 | 746701 | |

| 7461059 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 13 | 13.5 | 240 | M6 | 13.5 | 16 | 746701 | |

| 7461090 | SPEC | 4 files | Active i| Production is active. Expected lifetime: >10 years. | 16 | 13.5 | 350 | M8 | 13.5 | 20 | 746701 | |

| 7461060 | SPEC | 4 files | Active i| Production is active. Expected lifetime: >10 years. | 16 | 17.5 | 350 | M10 | 17.5 | 20 | 746701 |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | W (mm) | H (mm) | IR (A) | Ti | Tl (mm) | Pins (pcs) | Design Kit | Samples |

|---|

REDCUBE Terminals - 4power!

REDCUBE Terminals - 4power!

REDCUBE terminals are the most reliable high-power contacts on the PCB level. Low contact resistance guarantees minimum self-heating. Four different designs cover all leading processing technologies and offer a wide range of applications.

Characteristic:

- Flexibility in processing and connection technologies

- Highest current ratings up to 500 A

- Board-to-Board and Wire-to-Board solutions

- Extremely low self-heating

- Robust mechanical connection

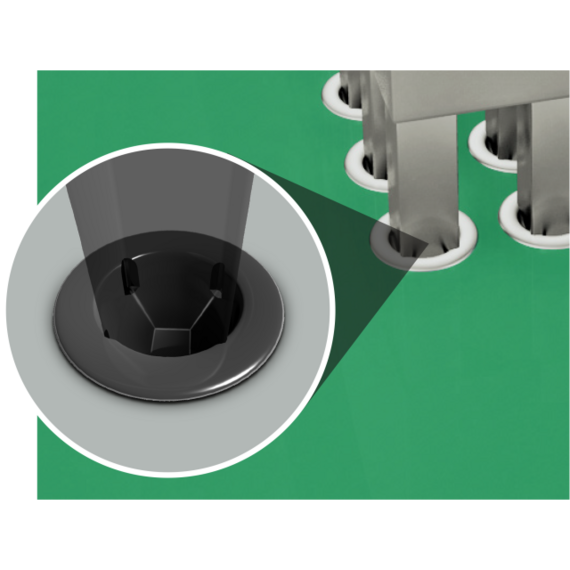

REDCUBE PRESS-FIT

Applications, Performance & Press-Fit Process

Applications

The current rating of REDCUBE PRESS-FIT is impressive. With the same ampacity, REDCUBE PRESS-FIT has the lowest heat development compared to other parts that supply power for PCBs.

- High current Wire-to-Board & Board-to-Board

- Mounting of copper bars

- Angled assembling of cable, PCB and housing

- Mounting of IGBT modules

Remarkable Performance

With the lowest Failure-In-Time value, REDCUBE PRESS-FIT is the most reliable technology on PCB. The FIT value is up to 30 times better than that of a SMD solder joint. REDCUBE PRESS-FIT is suitable for two-side mounting and allows very compact design of modules.

- Simple & quick processing

- No cold solder joints

- High process safety

- Low self heating

- Two-sided mounting of PCBs

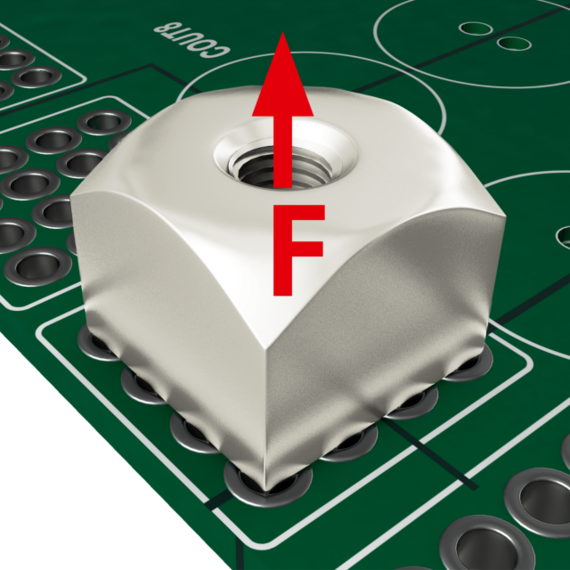

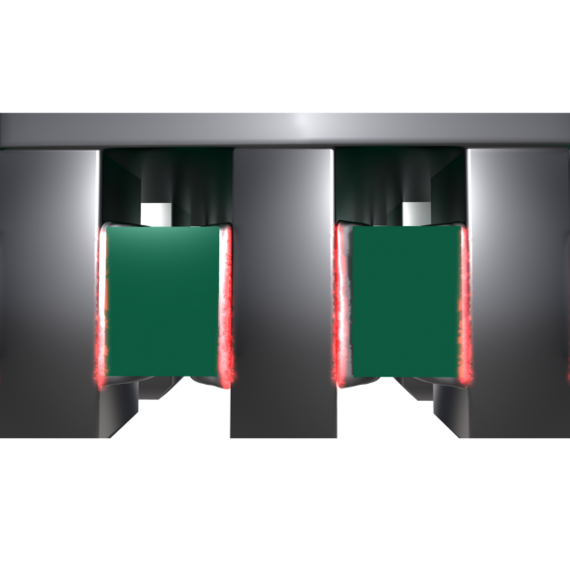

PRESS-FIT Process

Pressing the pins into the PCB, a high friction between pin and plated through-hole generates a homogeneous cold-welding between materials. No other technology transfers power up to 500 A at this low heat development.

- Homogeneous material transition between pin and through-hole plating

- Contact resistance less than 200 μΩ

- Gastight electrical and mechanical connection

- Extremely strong mechanical connection

Mates with

Assortments

Articles from this product series can be found in the following assortments:

Videos

#askLorandt explains: REDCUBE PRESS-FIT Process

Videos

Würth Elektronik Webinar: REDCUBE - Everything about high currents on the printed circuit board

Videos

Würth Elektronik Webinar: REDCUBE HighPower Terminals for ampacity of 50-500 A